DIOR reopens the doors of its iconic Montaigne Avenue location after more than 2 and a half years of renovation work. The 2,000-square-meter gallery, tracing the history of the house of Christian Dior, connects the present and future of this luxury powerhouse.

MC-Clic, an expert in drone design, has developed revolutionary drones for the Principality of Monaco, consisting of 80% 3D-printed components. These drones are designed to eradicate palm weevils, as per the request.

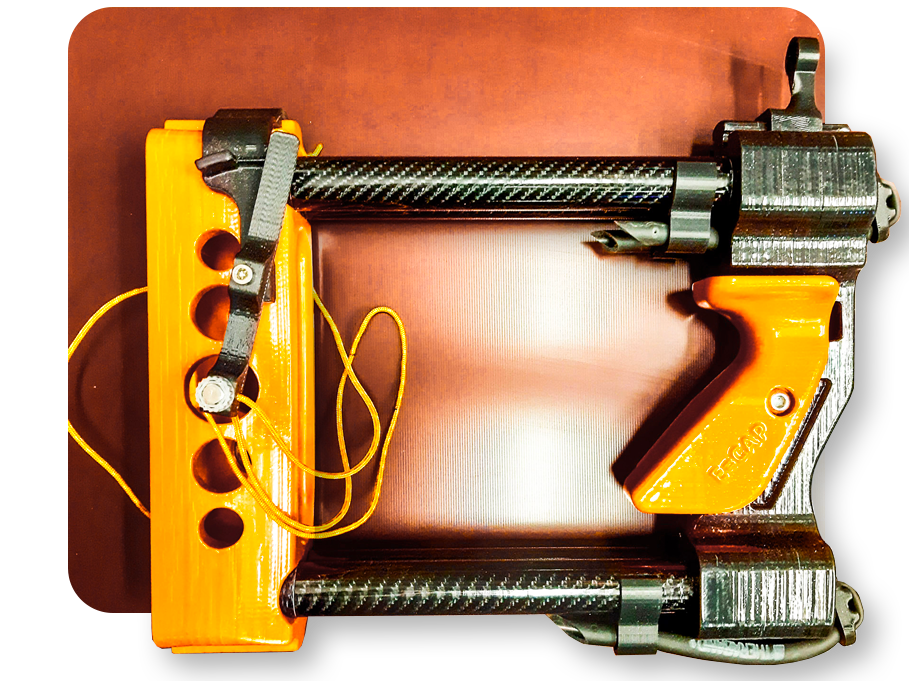

The Jérôme Trouillet workshop optimizes, prints, and sells customized "ElasTrainers" (educational handles created by Ludovic Cabar) with personalized palettes and grips (including the name, logo, color, etc.) to enhance the connection between the archer and the bow.

EMM Corporation offers its clients the opportunity to 3D print small batches of parts (10 to 200 pieces), thereby circumventing the expensive process of creating a plastic injection mold.

Mr. Riffaut, Methods / Maintenance / Continuous Improvement Manager at Bernadet, shares his experience with 3D printing:

Very impressive use cases of 3D printing in the medical field for orthopedic devices with the company M Orthopédie.

VOLUMIC is immensely proud, as a French manufacturer, to provide equipment to national protection and defense services. Today, various units within the gendarmerie utilize 3D printing to drive innovation in their work. Every day, the laboratories of the French Gendarmerie's Institute of Criminal Research (IRCGN) develop innovative devices to save precious time during genetic analysis.

The wildest toys that emerge from children's imagination are modeled and 3D printed for them by Mr. Fournier Montgieux.

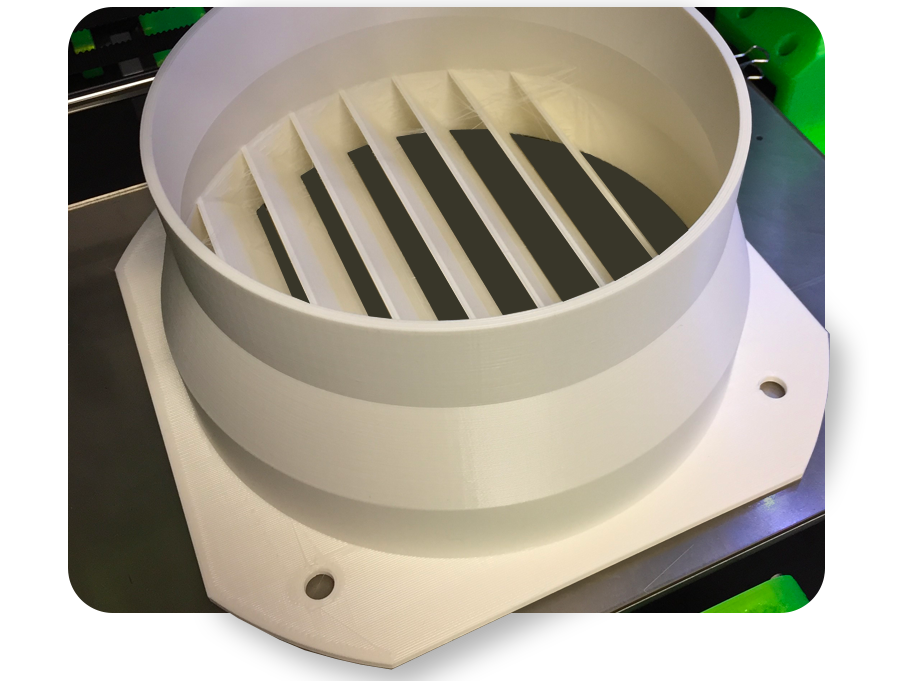

For its mosquito repellent stations, Qista employs 3D printing to produce a small technical component with a complex structure.

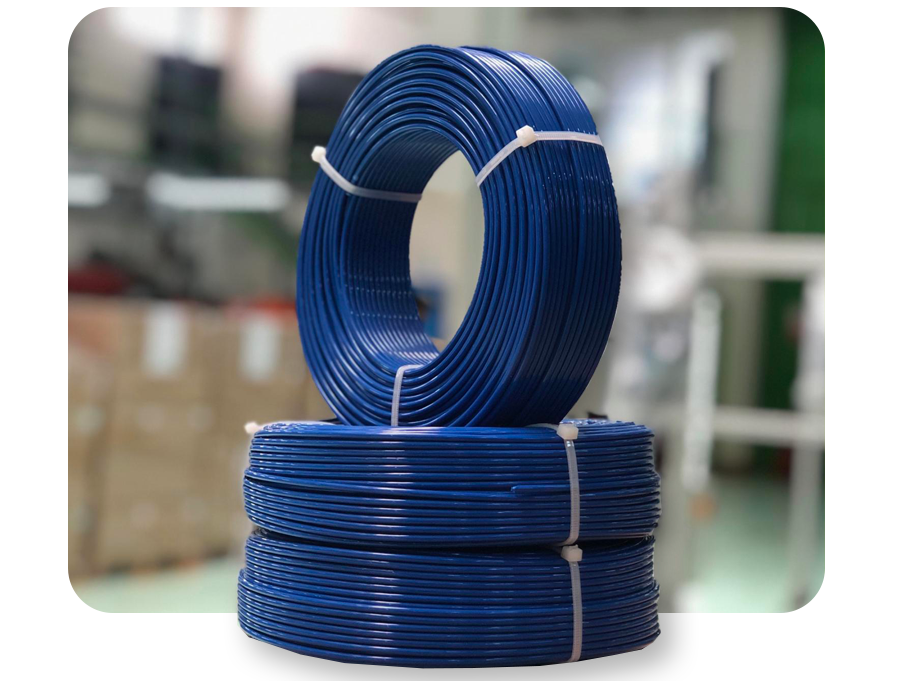

Corextrusion is a laboratory that leverages 3D printing to develop innovative and customized materials based on the specific needs of its clients.

Volumic 3D

- May/2023 -

08/07/2025 © All rights Reserved. GEMEA Interactive