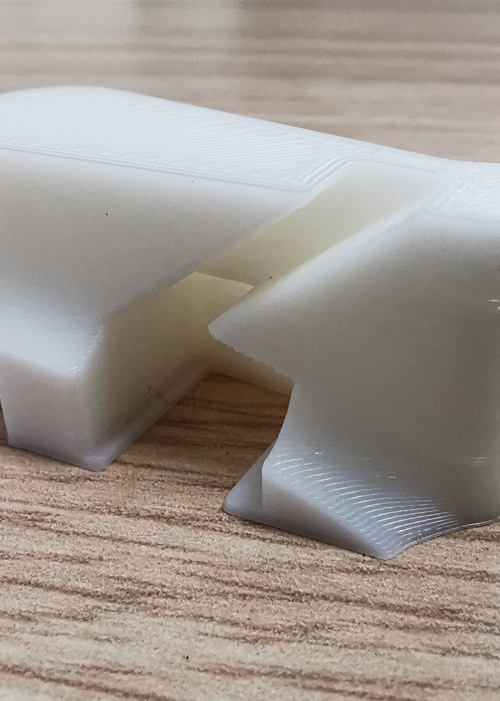

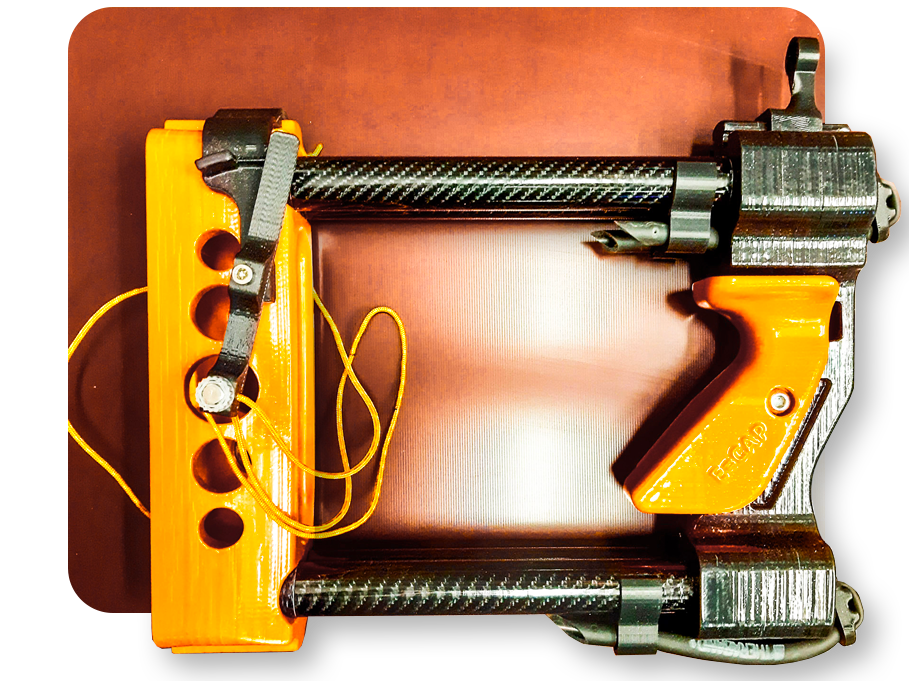

For its mosquito repellent stations, Qista employs 3D printing to produce a small technical component with a complex structure.

This pivotal component will serve as a connector between the machine's control board and the fan located in the mosquito repellent station's head. A straightforward and effective system for customers, eliminating the need for them to handle the connection themselves.

This component is 3D printed using a Stream Ultra printer and PLA, a biodegradable plant-based polymer that aligns with their environmental conservation efforts. This material also offers the advantages of being lightweight and durable.

3D printing facilitates customized and localized production, right within their workshops in Provence. On top of that, it injects agility into the internal design process. This results in significant time savings, heightened responsiveness, cost efficiency in manufacturing, and another stride forward in the Made in France movement.

Volumic 3D

- May/2023 -

22/10/2024 © All rights Reserved. GEMEA Interactive