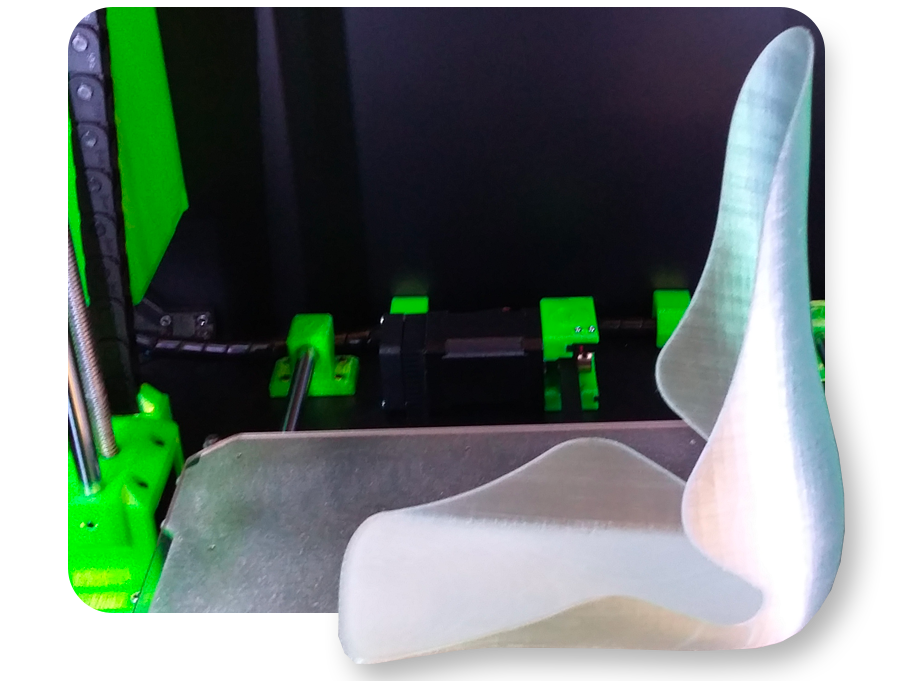

Exoneo utilizes 3D printing to create prototypes of prosthetic feet, aiming to achieve a model that perfectly matches the patient. Additionally, these prototypes serve as demonstration models for prospective clients.

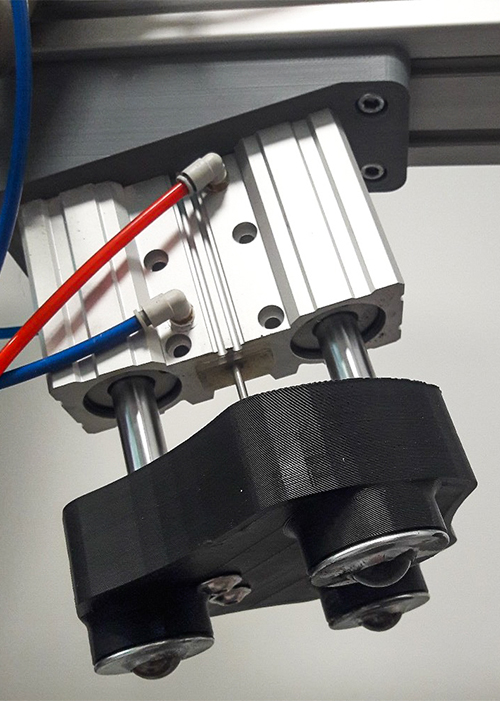

They also 3D print structural components for conducting CE certification tests. For instance, subjecting a piece to a 140kg load two million times over the course of a month to assess the durability of that component.

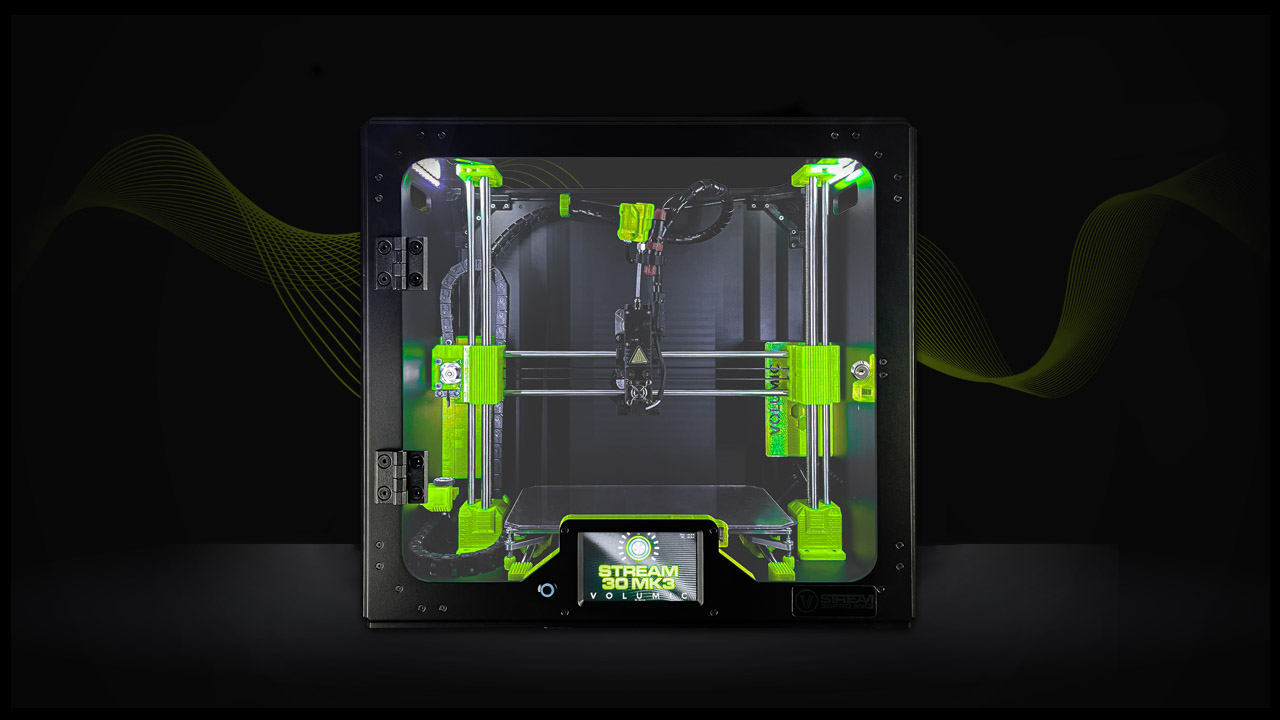

These components are printed using 2 Stream MK2 printers, using PLA, PETG, or even flexible materials based on the specifications of the various parts.

3D printing enables them to save both time and money, while also adjusting the volume, angle, and strength of the 3D printed components.

Volumic 3D

- Apr/2023 -

27/07/2024 © All rights Reserved. GEMEA Interactive