Whether you are a dentist or a dental technician, you can work with your own tools thanks to the rapid prototyping offered by our 3D printers.

Accurately and inexpensively produce all your denture, implant and jaw molds while saving considerable time.

And much more (+80 compatible materials)

Develop parts with innovative designs and complex geometries with high precision while maintaining complete confidentiality of your research.

Weight and strength are critical in the aerospace industry. You can manufacture elements that are as light as they are strong thanks to our multi-material 3D filament range: carbon fiber, bronze, copper, phosphorescent, etc.

Save time and budget by enhancing your customized tool creations and parts through the 3D printing manufacturing process, which significantly reduces development time and manufacturing costs.

Print your part directly without going through the costly production of a mold that requires small series production, you will get a better control of your raw materials and your costs with a stock always under control.

Volumic's number one priority has been to make reliable aerospace machines that researchers can rely on. From design to manufacturing, we have chosen materials that are both reliable and scalable to ensure the best performance over time.

Each printer is calibrated, tested and delivered ready to use with its complete software suite. Warranty and follow-up are among our priorities, and you will always have a competent technician available to answer your questions.

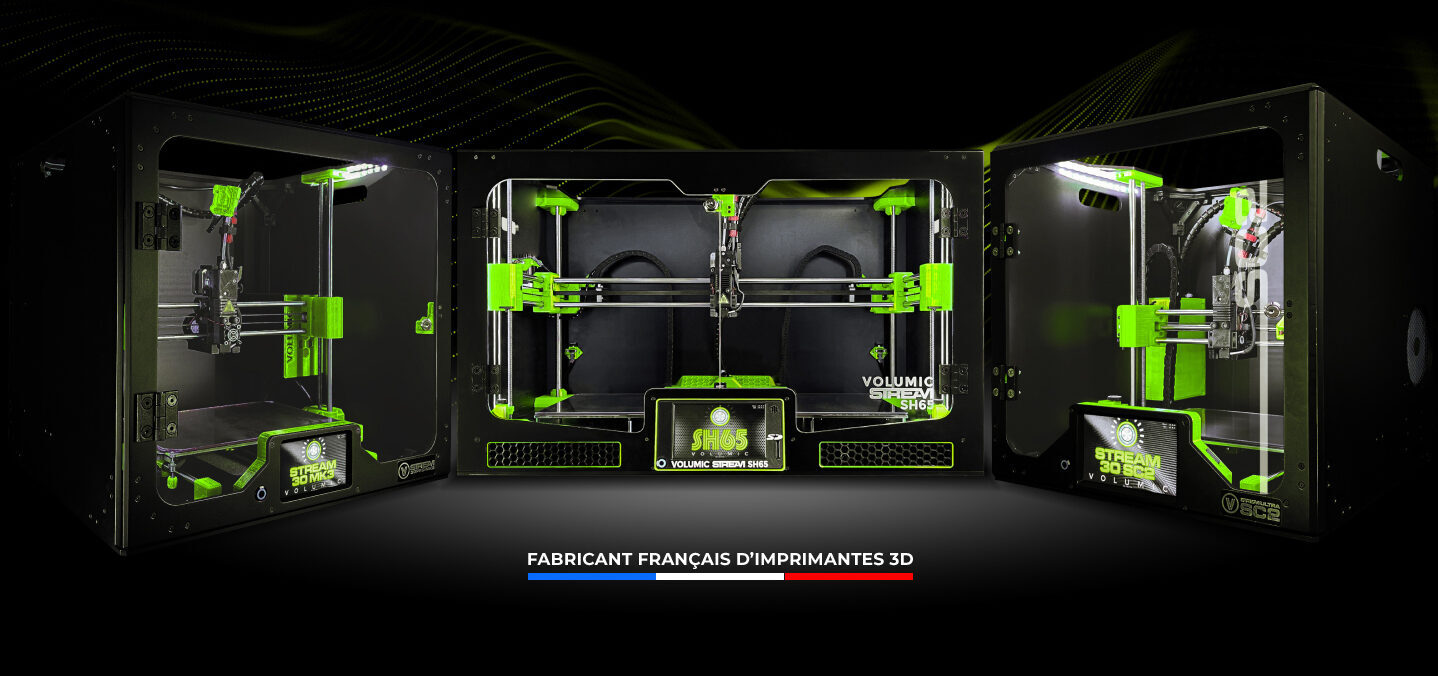

Above all, our printers are meticulously designed and meticulously manufactured in France, infused with both passion and precision. Elevating quality remains our paramount concern.

Volumic 3D

- Nov/2022 -

22/10/2024 © All rights Reserved. GEMEA Interactive