MC-Clic, an expert in drone design, has developed revolutionary drones for the Principality of Monaco, consisting of 80% 3D-printed components. These drones are designed to eradicate palm weevils, as per the request.

Mr. Riffaut, Methods / Maintenance / Continuous Improvement Manager at Bernadet, shares his experience with 3D printing:

For approximately 3 years, the French manufacturer of 3D printers Volumic has been working closely with the PSA Group for the production of parts, including functional prototypes, tooling, and finished components.

VOLUMIC is immensely proud, as a French manufacturer, to provide equipment to national protection and defense services. Today, various units within the gendarmerie utilize 3D printing to drive innovation in their work. Every day, the laboratories of the French Gendarmerie's Institute of Criminal Research (IRCGN) develop innovative devices to save precious time during genetic analysis.

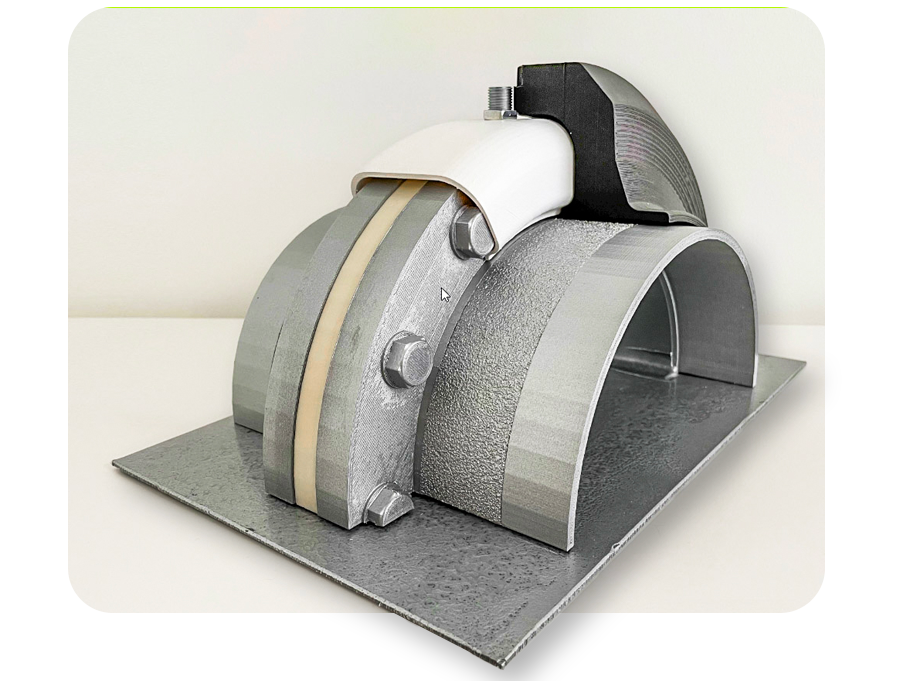

3X engineering uses 3D printing to create tools for applying products and repairing pressurized leaks, as well as for prototyping objects for presentations at exhibitions and producing small batches of tools.

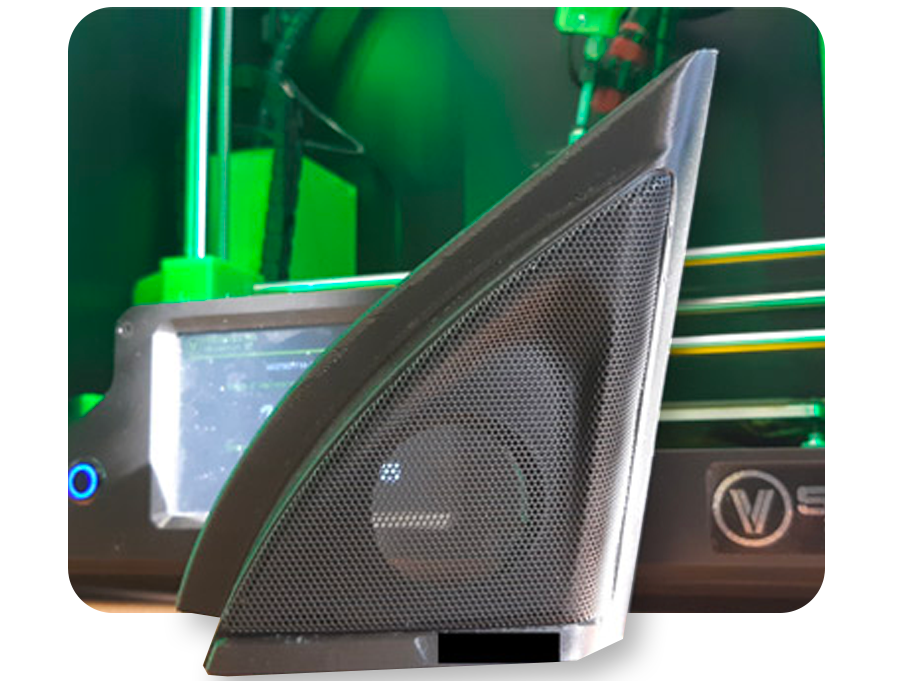

Nice Côte d'Azur Airport 3D prints components that are used in their daily operations, such as luggage diverters and radio supports for firefighting intervention vehicles.

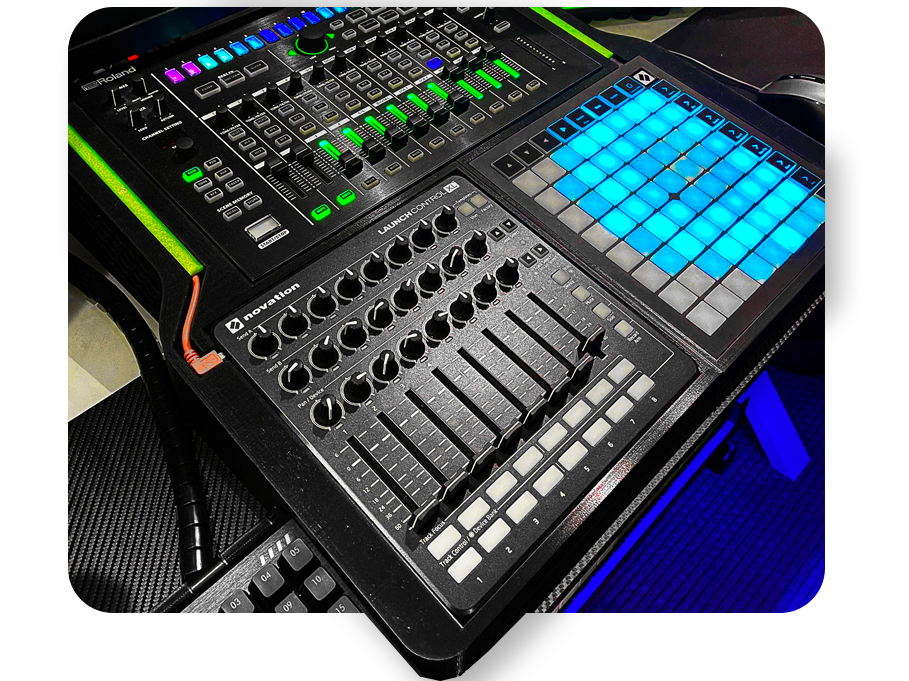

Electrophonique, an electronic music group, used 3D printing to create custom racks and docking stations for their various consoles, resulting in an ultra-optimized setup for their live performances and studio work.

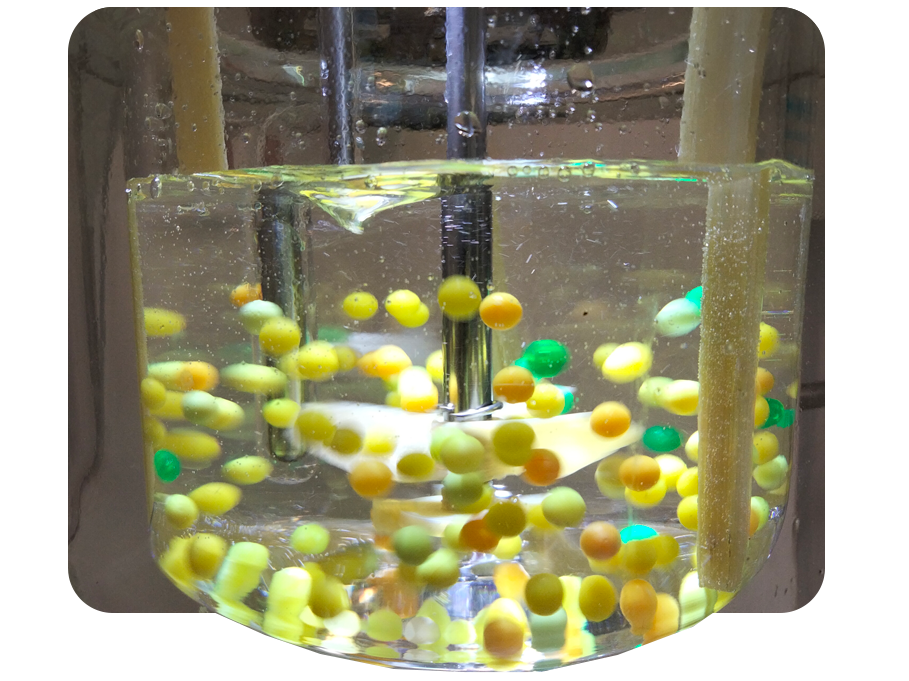

Zach System laboratories utilize 3D printing to create 3D-printed agitation devices such as propellers, turbines, and baffles. These are employed to replicate, on a reduced scale (1/100), the operation of an industrial reactor. This replication enables the in-depth investigation and validation of fluid hydrodynamics within the reactor, as well as the assessment of powder quality extracted post-crystallization process.

Within 72 hours, a thousand COVID-19 analysis test swabs 3D-printed.

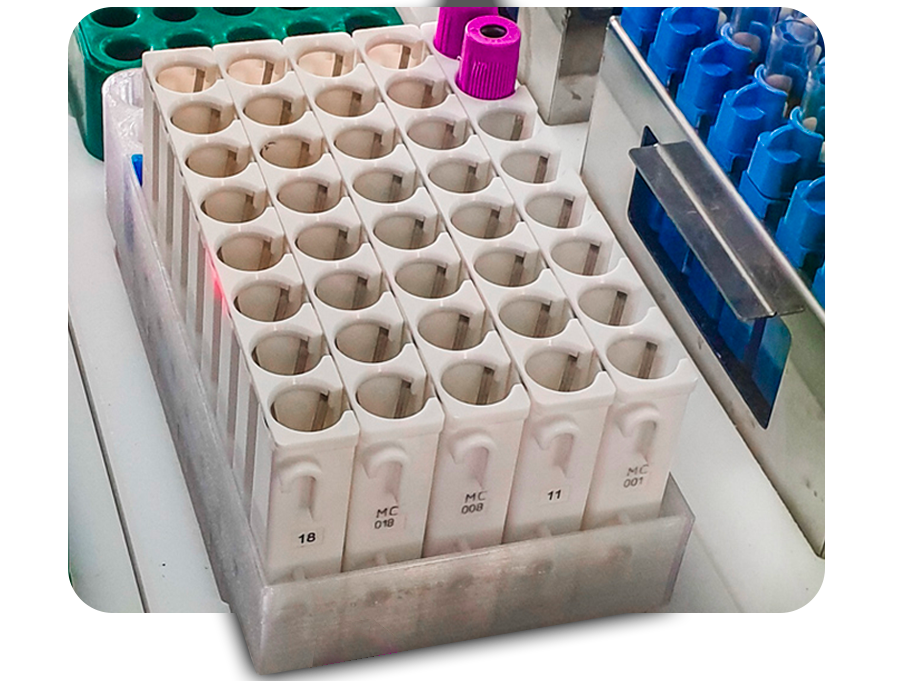

The Laboratories CERBALLIANCE, VOLUMIC and LaFERME3D have joined forces to provide an unprecedented solution to the issue of testing kit shortages for COVID-19 thanks to 3D printing.

Cerballiance Côte d’Azur laboratories have developed an interface for integrating automation within the laboratories.

Volumic 3D

- May/2023 -

30/06/2025 © All rights Reserved. GEMEA Interactive