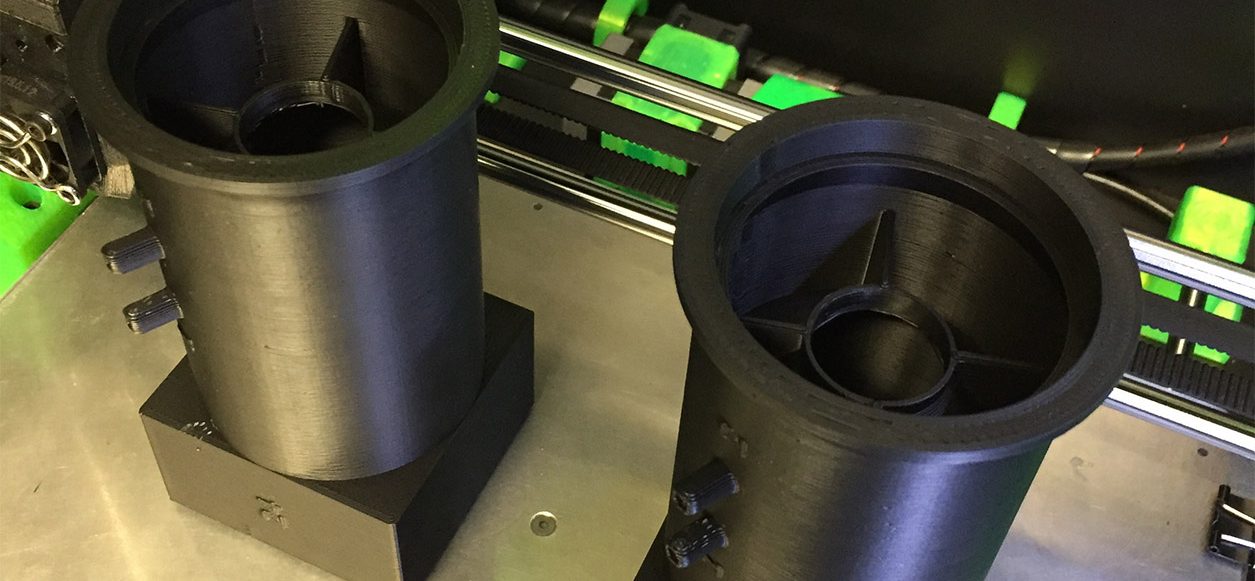

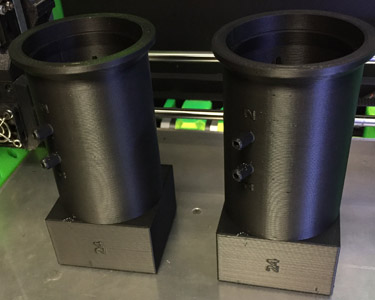

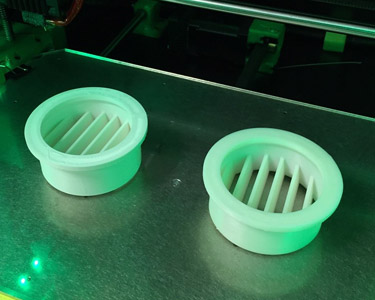

EMM Corporation offers its clients the opportunity to 3D print small batches of parts (10 to 200 pieces), thereby circumventing the expensive process of creating a plastic injection mold.

As highlighted by Mr. Pisani, CEO of EMM, "We enable industrial businesses to test new products before committing to mold production by introducing items created through 3D printing. The short lead time, quality of printed parts, and the chosen polymer all contribute to meeting the exact specifications required by our clients. Furthermore, we empower low-volume products to exist through 3D printing, eliminating the need for any mold-related investments."

During initial trials, the primary polymer utilized was PLA. However, it was subsequently substituted with Universal material to enhance mechanical properties and enable resistance against significant temperature fluctuations experienced by the parts during transportation, especially through maritime freight.

Volumic 3D

- May/2023 -

09/07/2025 © All rights Reserved. GEMEA Interactive