DIOR reopens the doors of its iconic Montaigne Avenue location after more than 2 and a half years of renovation work. The 2,000-square-meter gallery, tracing the history of the house of Christian Dior, connects the present and future of this luxury powerhouse.

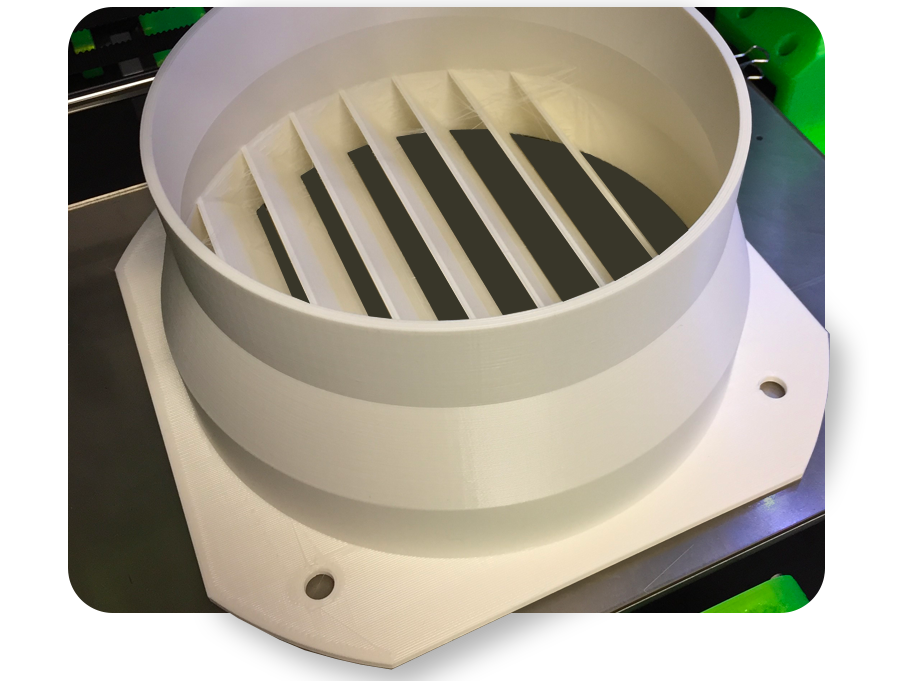

Around its magnificent central staircase, an exceptional artwork showcasing iconic and historic creations from the world of Dior has been recreated through 3D printing in the form of an immersive Diorama.

Since 2014, the ALIGHIERI agency has been modernizing the museography of the Christian Dior Museum, and has also designed the scenography for exhibitions such as "Dior, Legendary Images," "Dior, The New Look Revolution" in 2015, "Women in Dior" in 2016, and "Dior in Roses" in 2021. The project of La Galerie Dior, exceptional and on a new scale, led ALIGHIERI to propose a modular and replicable version, which would have been impossible to achieve with the background of heritage works. 3D printing offers and pushes these limits.

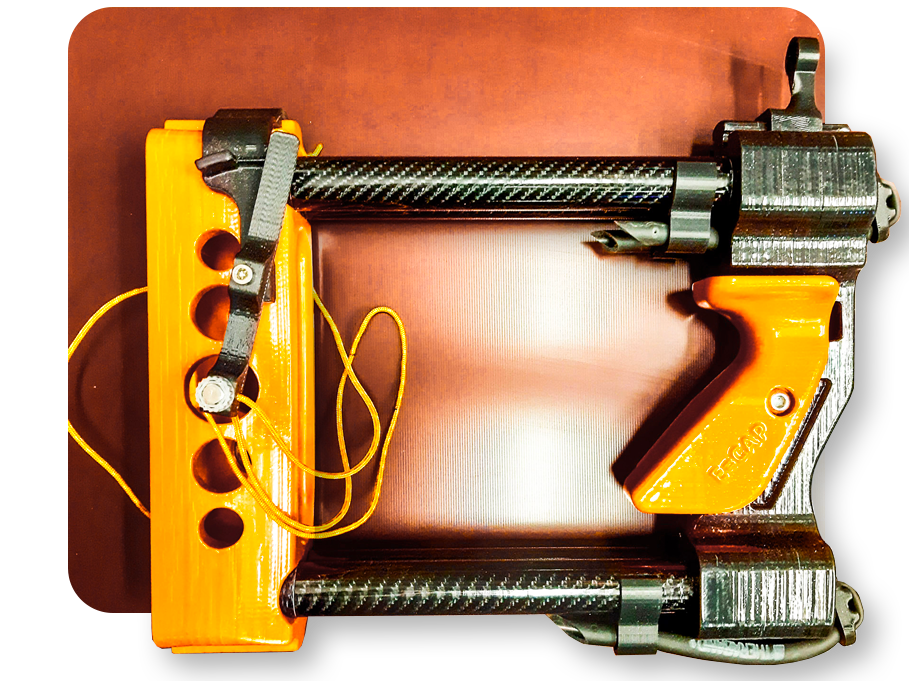

So, it is the 30 3D printers of LA FERME 3D that are used for this purpose. ©, exclusively designed by the French manufacturer VOLUMIC 3D, a pioneer in 3D printing in France, that ran day and night, including weekends, for over 6 months to produce one of the largest and most significant productions known to date.

Over 100,000 hours of production and more than a ton of bio-sourced raw material have been utilized to create the thousands of objects required for assembling this DIOR gallery masterpiece. It's a comprehensive expertise spanning across the Sud Region, Brussels, and Paris that enabled the successful realization of this challenge.

Stéphane Malaussena, co-founder of the VOLUMIC 3D brand, expresses:

"Beyond the accomplished technical feat, this project was executed at full speed in just 6 months with our latest generations of machines, which worked around the clock, 24/7, with exceptionally high efficiency. To achieve the seemingly impossible, aside from the quality of the printed parts, it's the endurance and reliability of our printers that made the difference in the success of this project."

The final result is truly breathtaking, leaving every visitor speechless, as the 3D productions are regarded as exact replicas of the original products. The goal of achieving a perfect trompe l'oeil has been accomplished through the additive manufacturing expertise of the La FERME 3D teams. © coupled with the high level of precision of the 3D printers from the Tricolore brand.

This creation of nearly 1500 objects, faithful replicas of the brand's iconic creations, was made possible through the collaboration between the ALIGHIERI Agency founded by Simon Jaffrot and Noémie Bourgeois, and LA FERME 3D. © located in Saint Rémy de Provence, under the direction of Florent Carasco.

Once again, 3D printing has pushed the boundaries of what's possible, this time in the realm of luxury through a French ecosystem of innovation.

Volumic 3D

- May/2023 -

22/12/2025 © All rights Reserved. GEMEA Interactive