Today’s students are tomorrow’s workers and that’s why 3D printing is an essential technological tool to effectively prepare students for the world of work. Go from theory to practice with our 3D printers and reinvent education by complementing the learning of traditional subjects.

By combining creativity and modernity, students and teachers will be even more motivated with the3D printer for school.

And much more (+80 compatible materials)

Designed to make real volume creations, a 3D printer is also a good multipurpose teaching aid.

A 3D printer allows for the creation of various objects such as models, customized accessories, and miniatures, with maximum dimensions of 30 x 30 x 30 cm. This equipment operates using a computer (with dedicated software) and a plastic material, typically in powder form. The design of the object to be created is done through the software, which is used to develop 3D plans. This file is then converted into a large number of 2D files, which are sent to the printer. The printer will interpret the given instructions to produce the desired object in three dimensions. This process can be analyzed within the framework of a specific introduction to this technology. The steps leading up to the actual creation of the chosen model have educational value, not only in computer science classes. One must learn to design what will be made, create the plans, and then "slice" them. The operation of the3D printer is also done under the teacher's supervision. Educational applications for all levels.

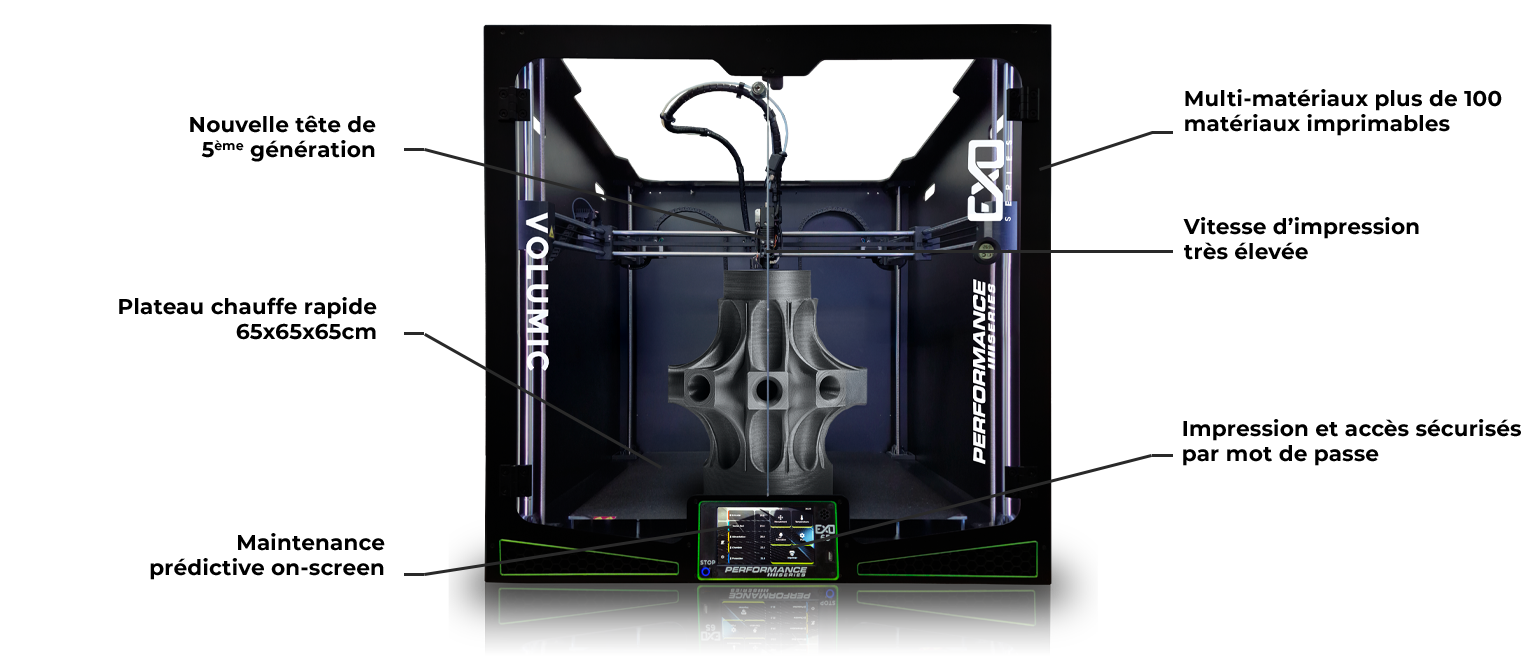

Develop parts with innovative designs and complex geometries with high precision while maintaining complete confidentiality of your research.

Weight and strength are critical in the aerospace industry. You can manufacture elements that are as light as they are strong thanks to our multi-material 3D filament range: carbon fiber, bronze, copper, phosphorescent, etc.

Save time and budget by enhancing your customized tool creations and parts through the 3D printing manufacturing process, which significantly reduces development time and manufacturing costs.

Print your part directly without going through the costly production of a mold that requires small series production, you will get a better control of your raw materials and your costs with a stock always under control.

Volumic's number one priority has been to make reliable aerospace machines that researchers can rely on. From design to manufacturing, we have chosen materials that are both reliable and scalable to ensure the best performance over time.

Each printer is calibrated, tested and delivered ready to use with its complete software suite. Warranty and follow-up are among our priorities, and you will always have a competent technician available to answer your questions.

Stream 3D printers allow you to print all types of prototypes and innovative tools in more than 30 different materials with a level of precision and speed among the best on the market.

Crafted with meticulous precision and a systematic approach, Stream 3D printers are engineered for seamless daily operation, devoid of any unwelcome surprises, courtesy of their design founded upon tried-and-true, dependable components.

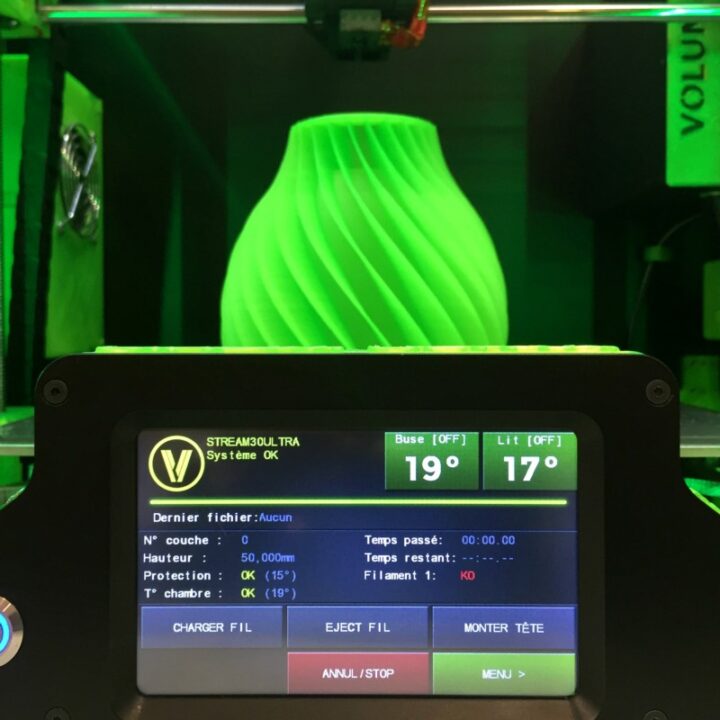

Delivered fully assembled and pre-calibrated, accompanied by their software suite, you'll be able to initiate your inaugural 3D print shortly after unboxing. This is made possible through the inclusion of test objects on the memory card.

Designed and manufactured in France, we offer you all the assistance and after-sales service during and after the warranty period. To ensure the best services, your printer can be picked up within 24 hours and returned within 72 hours (simple maintenance).

3D printing is an emerging technology accessible to a broad spectrum of users. However, our team of dedicated enthusiasts brings over 15 years of experience in the realm of 3D design.

The colors of the Stream series can be personalized to match your company's branding, ensuring alignment with your establishment's visual identity.

Eliminate uncertainty from your investments; Volumic presents upgrade kits that enable the evolution of your Stream printers. Feel free to reach out to us to learn more about this innovative service.

Complete compatibility with your 3D CAD/CAM software. Our software seamlessly imports STL, STEP, 3DS, OBJ formats from major 3D programs such as SolidWorks, Catia, 3Dsmax, Blender, Sketchup, Cinema4D, and more.

Our 3D printers are self-sufficient, capable of functioning and printing independently without the need for a computer connection. This convenience is facilitated by the presence of a memory card housing your 3D files. Furthermore, the USB connection permits direct control from a computer if desired.

Above all, our printers are meticulously designed and meticulously manufactured in France, infused with both passion and precision. Elevating quality remains our paramount concern.

Volumic 3D

- Nov/2022 -

16/02/2026 © All rights Reserved. GEMEA Interactive