Volumic 3D is delighted to announce its collaboration with Ascendance Flight Technologies for creating functional prototypes of this groundbreaking new airborne vehicle. A special focus on 3D printing was dedicated to producing large-scale fuselages.

In terms of figures, Atea represents:

Introducing Atea, a low-noise, low-carbon Vertical Takeoff and Landing (VTOL) aircraft based on Sterna, a unique hybrid propulsion technology developed by Ascendance.

Featuring an extensive range and rapid turnaround time, it meets the operational demands of today's air mobility providers for a wide array of missions, including passenger transport and emergency medical services;

The entire aircraft has been designed in compliance with the requirements of EASA's SC-VTOL regulations. The airplane also meets the current operational demands of Air Ops regulations regarding flight routes and flight reserves.

Thanks to its unique hybrid propulsion system using a blend of kerosene and batteries for optimized fuel consumption, flying more cleanly is now achievable. However, this is just the first step, thanks to a modular architecture that is also compatible with a future hydrogen-powered aircraft or Sustainable Aviation Fuel, aiming to achieve Net Zero Emissions.

The integration of vertical rotors into the wings, along with a disruptive fuselage design and propulsion by the hybrid-electric system, brings a drastic improvement to Atea's acoustic signature. This noise reduction opens up an entirely new range of missions, allowing flights closer to urban areas and in environments that were previously inaccessible due to noise constraints.

Atea has been designed to provide a sustainable alternative to conventional aviation while maintaining the same level of performance as current aircraft. Thanks to its "lift and cruise" configuration with fixed wings, Atea is capable of flying on regional or intercity routes.

The aircraft is designed to meet the same level of safety requirements as current conventional aviation, while providing an additional level of security by ensuring the ability to continue flight and safely land in the event of a single failure. The combination of two energy sources in the hybrid propulsion system also offers redundancy by design, further enhancing the safety and operational range of the aircraft.

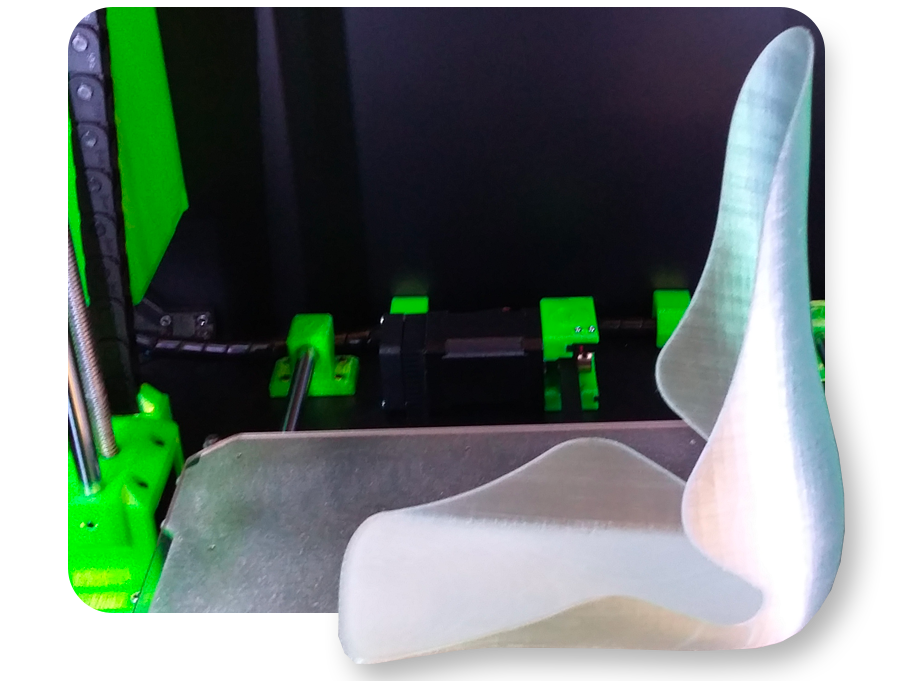

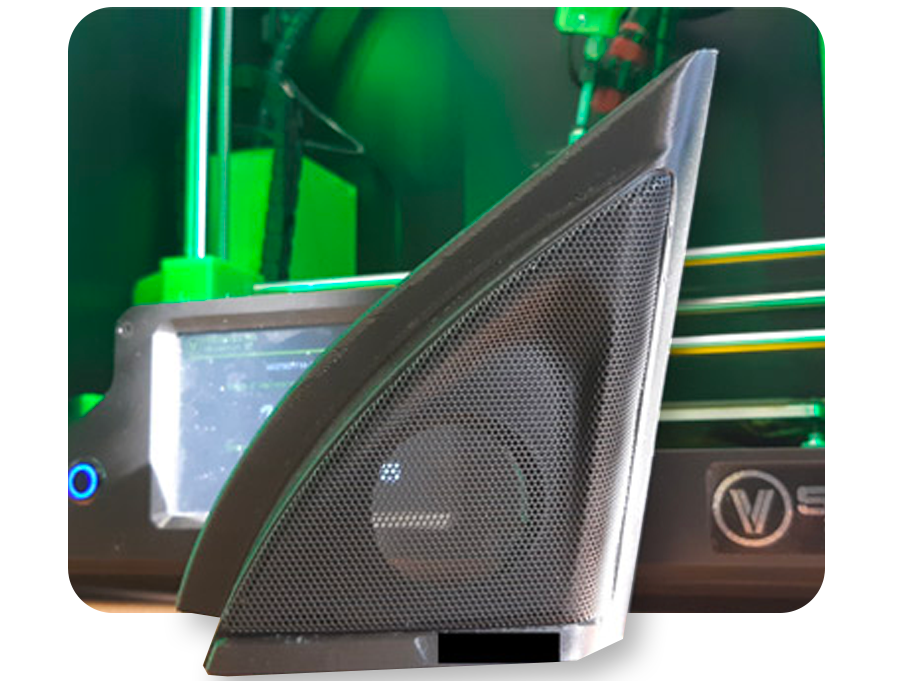

The selection of lightweight, durable, and recyclable materials formed the foundation of AFT's specifications. The project's success was attributed to remarkably short prototyping times, allowing real-time adjustments to be made to designs and models.

Wind tunnel and flight tests could thus be conducted nearly daily. The large-format printing capabilities of our latest 3D printers provided the final touch to the project, producing models reaching up to 65cm in size.

Volumic 3D

- Apr/2023 -

26/01/2026 © All rights Reserved. GEMEA Interactive