Volumic is thrilled and proud of the test and the rating given to our latest 3D printer, the SH65, by 3D Natives.

"Published on September 15, 2022 by Elliot S.

Pioneering the market for professional desktop FDM printers in France back in 2014, Volumic stands as the first French manufacturer of high-performance desktop extrusion machines. This positioned them to collaborate swiftly with prominent corporate entities such as the SEB Group, Stellantis (formerly PSA), Ariane Group, Safran, and Thales. Their achievements have been acknowledged on multiple occasions, including recognition at CES in Las Vegas in 2020 and invitations to Élysée Palace to exhibit at the "Fabriqué en France" fair in both 2020 and 2021. Volumic is a recognized player in the realm of additive manufacturing.

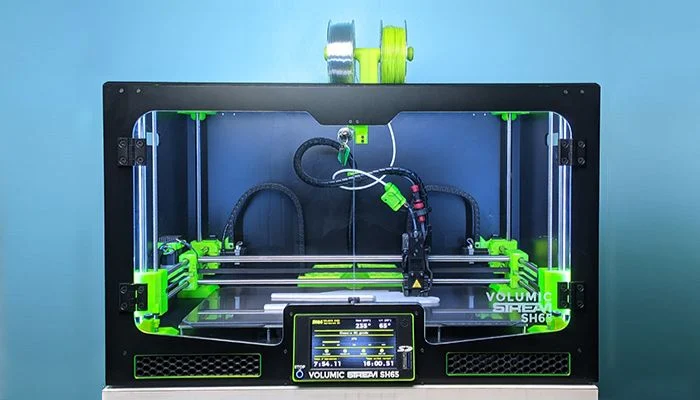

In October 2021, Volumic unveiled the SH65: a high-performance, large-volume 3D printer that complements their existing range. This new printer features an improved motion system tailored to its dimensions and, with an entry price of €9,200 excluding taxes, positions itself as a premium machine with performance levels similar to the SC2. To ensure its real-world performance, the SH65 was launched after a 10-month pre-series period. What applications was the SH65 developed for? What kind of performance does it deliver? Discover our review of the Volumic SH65 now.

At first glance, the SH65 3D printer appears impressive and is delivered on a pallet, within a spacious box, safeguarded by several foam blocks. Unpacking is straightforward as the top of the wide box is removable, enabling easy access to the 3D printer for lifting and moving it to the workspace using its side handles.

Within the box, the 3D printer arrives partially assembled. Numerous accessories are included, such as a spool of Ultra PLA, gloves, a can of 3DLAC adhesive, a pair of cutting pliers, a scalpel with replacement blades, a USB cable and a power cable, a 7mm wrench, 2 unclogging needles (for the nozzle), a spatula, a USB SD card reader, a central filament holder, and comprehensive documentation in both paper and digital format on the provided SD card. The SD card also contains software and sample files (STL and G-code).

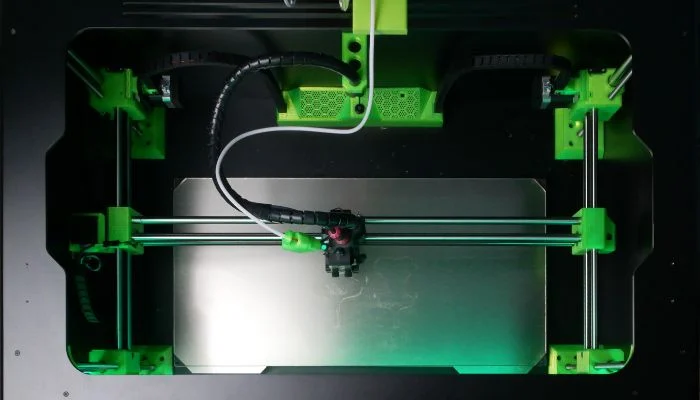

Measuring 900 x 500 x 480 mm and weighing 55 kg, the SH65 is a desktop FDM machine with a generous print volume of 650 x 300 x 300 mm. It is recommended to carry it with two people and to make sure that the space on which it is positioned is strong enough (the manufacturer recommends a work surface that can support more than 80kg).

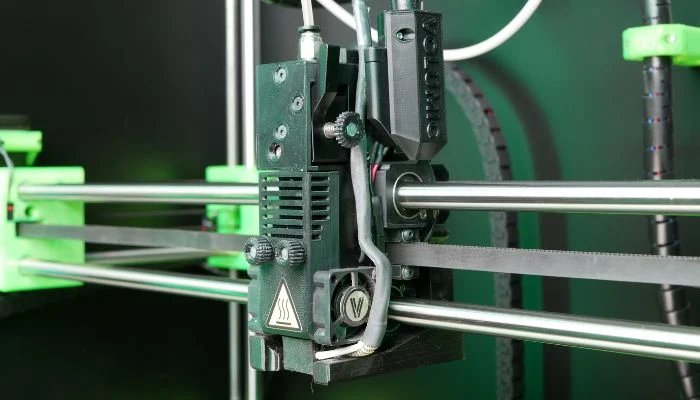

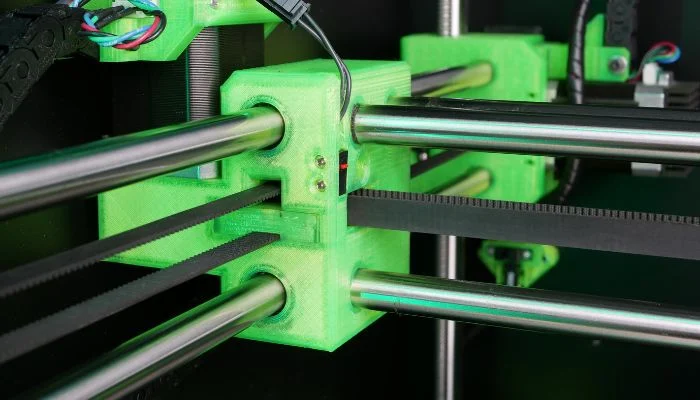

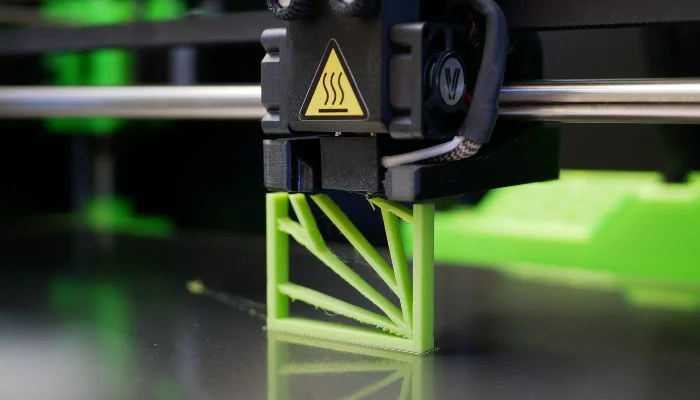

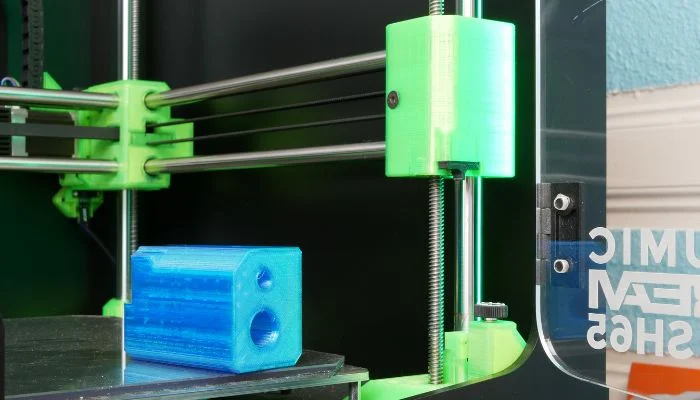

In terms of components, the Volumic SH65 is built upon a 6mm aerospace-grade aluminum chassis, coupled with a Cartesian X and Y movement system utilizing tripled 12mm chromed ground rods, ball bearings, and 3 Nema 23 motors (2 for the Y-axis and 1 for the X-axis). The Z-axis employs 4 Nema 17 motors and 4 16mm rods to ensure the first layer is parallel to the bed. For printing, the SH65 features a customized extruder, specially crafted by Volumic using Bondtech components, and a bespoke bimetallic hotend with parts from E3D.

Due to its horizontal structure, Volumic has chosen to have the longest axis in the Y direction, whereas the longest axis is typically in the Z direction. Volumic shared that this decision was based on customer feedback regarding the usefulness of an extended Y axis. FDM-printed parts are anisotropic, which means they can be more fragile along the Z axis. By opting for this longer Y axis and strategically orienting parts, it becomes possible to enhance the mechanical properties, particularly the tensile strength, of larger dimension prints.

At the front, a wide double-hinged transparent acrylic door provides an overall view of the printing enclosure and easy access to the print bed. A sleek 7-inch color touchscreen occupies the center. The sides, rear, and top of the printer are made of aerospace-grade aluminum plates, while the upper part features a large opening that can accommodate an optional enclosure (complete with lifters and ABEK/HEPA filter).

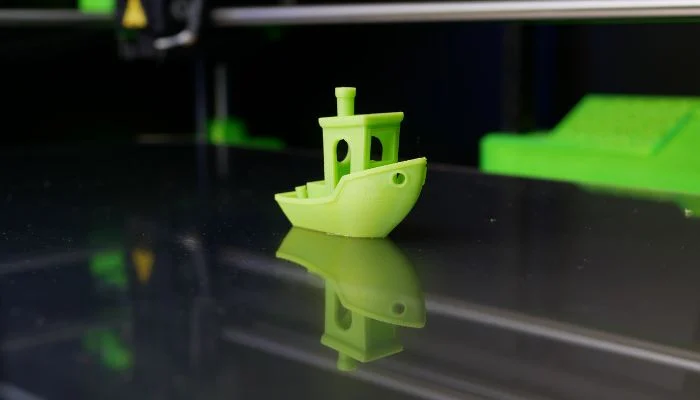

Although the SH65 3D printer stands out due to its dimensions, it still embodies the brand's signature elements, including various 3D-printed components in Volumic's distinctive fluorescent green color. Additionally, subtle elements such as the black ventilation grilles are present. The manufacturer offers these models on its website for easy replacement when needed.

Since the SH65 arrives partially assembled, all that's needed is to take it out of its shipping box, set it up on a workspace, and remove all the protective foam blocks. The only assembly required is for the filament spool holder, which comprises several 3D-printed parts, a screw, and two PTFE tubes to guide the filament to the print head.

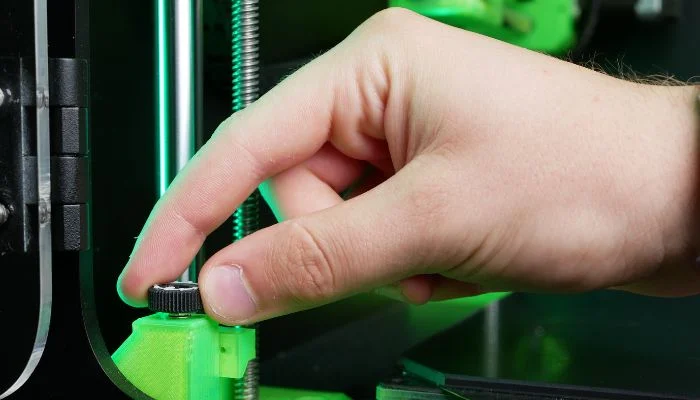

From the very first startup, the printer is ready to be loaded with filament, and it's recommended to perform a print head leveling (it's already calibrated, but adjustments might be needed due to transportation, so it's advised to double-check it).

Regarding the leveling process, it involves adjusting the parallelism of the print head in relation to the bed. The bed itself is stationary, and the entire X/Y movement system is mobile in the Z direction due to 4 independent Nema 17 motors. The height of each corner of the bed can be slightly adjusted to account for any possible lack of flatness. Given the size of the print bed, it's possible that it might not be perfectly level. If necessary, this can be addressed by using the 11 screws positioned under the bed to raise or lower specific sections.

The manual provided with the 3D printer is quite comprehensive, though available only in French. It guides the user through the setup process and provides recommendations for correctly adjusting printer settings and mastering additional features. The manual also offers advice for preventive maintenance and includes the procedure for repacking the printer in case of a return for service.

In addition to the paper manual and digital files on the SD card provided with the SH65 3D printer, the manufacturer's website offers slicer profiles, firmwares, software, utilities, 3D files of the printed parts of the machine, and documentation. On the customer support (SAV) page, the manufacturer based in Nice provides a knowledge base where users can find answers to the majority of questions related to the use of their machines. It's worth noting that users can also submit a new question if their specific issue isn't already covered.

The only negative aspect we observed was that when both front doors were locked, the right door could exert slight pressure on the left one, potentially affecting the door-closure sensor. We brought this to the attention of Volumic's team, and they informed us that they have addressed this issue with a revision in their newer machines.

For its machines, Volumic develops its own motherboards, the Ultralumics. The manufacturer relies on a highly customized version of Marlin to control its printers.

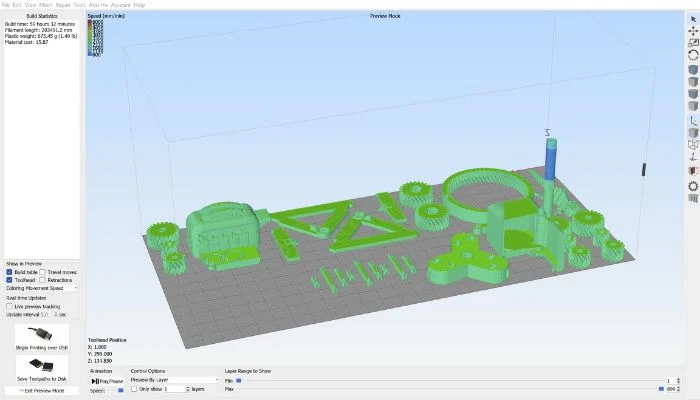

In terms of slicing software, Volumic recommends using Simplify3D for optimal results, but the manufacturer also provides pre-configured profiles for Cura software. Simplify3D is one of the oldest slicers in the market and offers advanced features. It is recommended for its high degree of customization and performance, and the profiles provided by the manufacturer are well-developed for it. Once models are sliced in Simplify3D, the resulting G-code can be saved on the SD card or sent to the printer using the printer's remote control interface, accessible via the machine's IP address. This interface enables starting prints and managing all printer settings through a local network connection.

However, Volumic doesn't neglect users of Cura and has also developed profiles for the popular free slicing software. When using Cura, it's notably possible to natively connect the printer to the slicer through the local network by inputting its IP address. Other parameters, such as advanced infills and support structures, are also available.

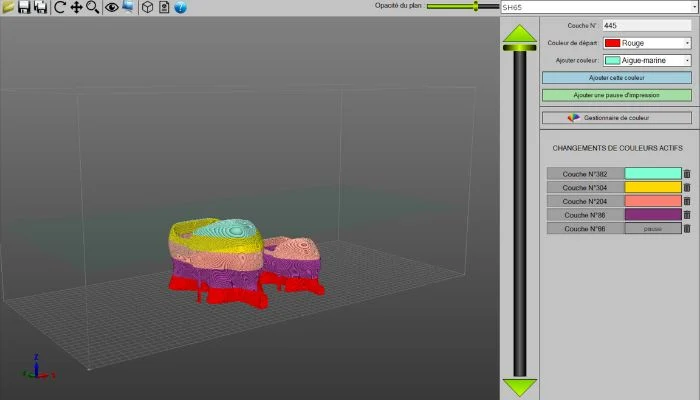

Based on customer feedback, the manufacturer has confirmed that they are currently working on new profiles to enable the use of other slicers such as SuperSlicer or PrusaSlicer. While Volumic relies on third-party software for slicing, they have also developed some interesting in-house tools. They offer Volunet, a farm management software that allows users to control multiple machines simultaneously; Verify3D, a 3D file viewer; and Colorify3D, a tool that allows users to segment a G-code file, pause the print, and manually change filament, facilitating simple multi-color prints.

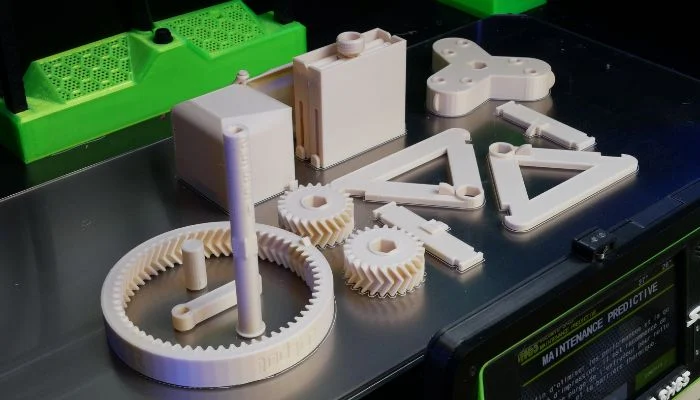

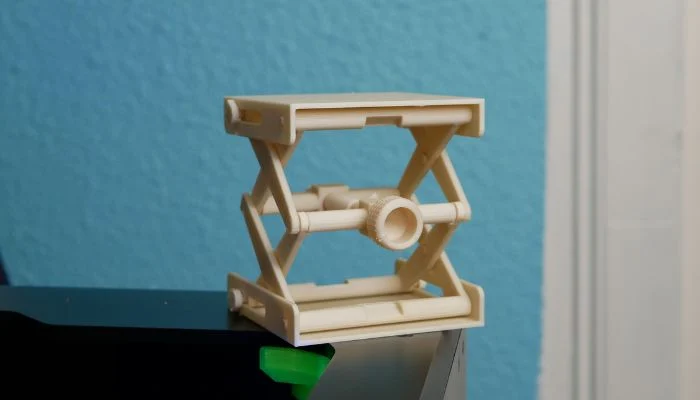

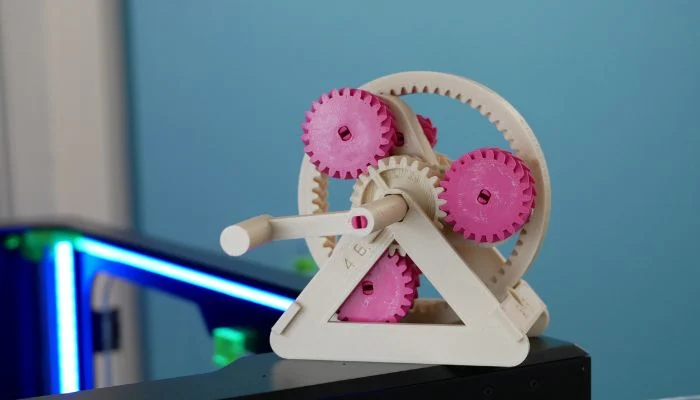

Once unpacked and set up, the SH65 3D printer is ready to print. We began our prints using the provided Ultra PLA filament and the pre-configured profiles in Simplify3D. From the very first print, we achieved a finely detailed finished piece that accurately reproduced all the details of the model. The printing profiles provided by the manufacturer enable fast printing while delivering excellent results.

During our initial prints, we noticed a minor issue with the provided filament spool holder. It vibrated during printing and occasionally obstructed the movement of the print head. After designing, printing, and installing a new filament spool holder using Ultra PLA, we swiftly resolved this issue.

Once our PLA Ultra prints were completed, we moved on to experimenting with PETG Ultra. Again, the Simplify3D profiles ensured smooth printing right from the first attempt. Each print accurately reproduced the details of the models, and the bottom surfaces of the pieces exhibited a smooth finish, thanks to the magnetic glass print bed and the provided 3DLac adhesive spray. During printing, the parts adhered firmly to the heated glass bed, but they detached easily once the bed cooled down, facilitating effortless removal. In addition to Volumic's PETG Ultra, we also used PETG from other manufacturers, confirming the SH65's compatibility with third-party materials.

In general, the manufacturer has put in significant effort to streamline the user experience. Thanks to the pre-configured profiles, compatibility with various tools, and the intuitive menu on the printer's touchscreen, getting started with the SH65 is a straightforward process.

We continued the test by printing a variety of models using ABS filament. The absence of an upper enclosure by default on the SH65 revealed issues with warping, delamination, or parts detaching from the print bed mid-print. Therefore, it will be necessary to equip the optional enclosure when aiming to print with technical materials sensitive to temperature changes.

Having a second extruder for printing complex geometries with soluble supports would have been beneficial. As it stands, supports will need to be made from the same printing material as the rest of the part. However, the machine's precision makes removing supports relatively easy.

We also printed with TPU, showcasing the SH65's capabilities in flexible material printing and its compatibility with this filament. The only issue we encountered was related to filament insertion. When inserting the filament into the filament end sensor, the flexibility of TPU caused difficulties in engaging the sensor properly. By adjusting the filament insertion, we eventually managed to insert it correctly and start the prints. These prints proceeded as planned, without any issues like stringing or other defects.

Finally, we tested the Universal Ultra filament, a PLA+ like thermoplastic developed by Volumic. Once again, the prints turned out successfully, and the material is easy to work with due to the provided profiles.

Regardless of the material used, the large printing volume offered by the SH65 is a real asset. This allows for large prints or the ability to print a significant number of parts simultaneously by filling the bed with multiple models.

Volumic 3D

- Apr/2023 -

30/06/2025 © All rights Reserved. GEMEA Interactive