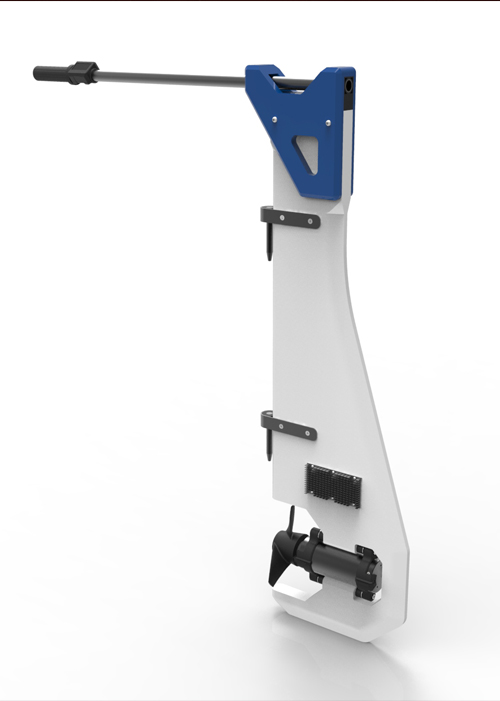

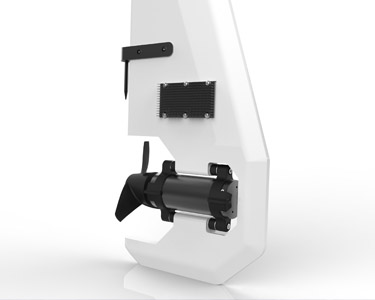

The company CamGau, situated in the port of Nice, has developed the E-Safran, an electric propulsion system tailored for "pointus" and other traditional Marseille boats. Numerous components, including the propeller, have been 3D-printed using Volumic 3D printers for this innovation.

Indeed, electric propulsion demands specialized propellers due to high rotational speeds. This PETg-based propeller, infused with short carbon fibers, is crafted using Volumic 3D printers. The material boasts extraordinary attributes arising from the fusion of PETg and carbon: remarkable mechanical strength, resistance to abrasion, water, and UV rays.

Due to the complexity of the component's geometry and the required properties, only 3D printing enabled the creation and validation of this novel propeller design. This design would have been challenging and costly to produce using molds or machining processes.

This innovation has led to cost reduction for small-scale production. Extensive endurance and durability tests were conducted on the vessel "Lou Passagin," which operates for 9 hours a day over a span of 6 months, now spanning 5 years. The propeller has endured numerous docking maneuvers, subjecting it to substantial stress.

Volumic 3D

- May/2023 -

12/07/2025 © All rights Reserved. GEMEA Interactive