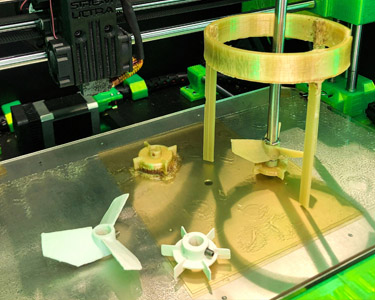

Zach System laboratories utilize 3D printing to create 3D-printed agitation devices such as propellers, turbines, and baffles. These are employed to replicate, on a reduced scale (1/100), the operation of an industrial reactor. This replication enables the in-depth investigation and validation of fluid hydrodynamics within the reactor, as well as the assessment of powder quality extracted post-crystallization process.

These components are 3D printed using a Volumic Stream Ultra printer using PLA, Universal, and PEKK materials. This selection of materials ensures the durability required to withstand both mechanical and chemical abrasion resulting from contact with solvents.

Chemical processes are initially tested at a laboratory scale in miniature, and subsequently replicated at an industrial scale.

3D printing enables complete control and mastery over the scaling of various components within the chemical process, thereby ensuring the accuracy of tests conducted in the laboratory.

Volumic 3D

- May/2023 -

15/07/2025 © All rights Reserved. GEMEA Interactive