Corextrusion is a laboratory that leverages 3D printing to develop innovative and customized materials based on the specific needs of its clients.

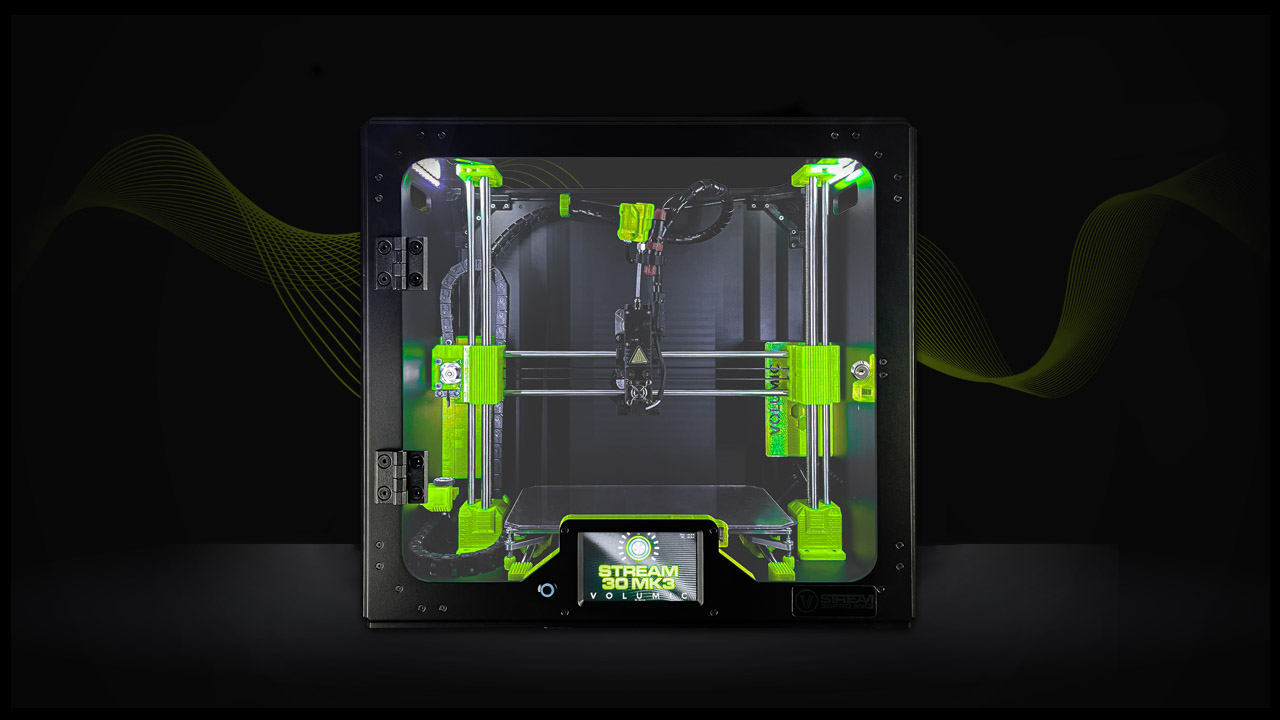

In order to assist in the search for optimal compositions and printing profiles, Corextrusion 3D prints test specimens using various materials, which are subsequently subjected to tests for factors such as flexural and tensile strength.

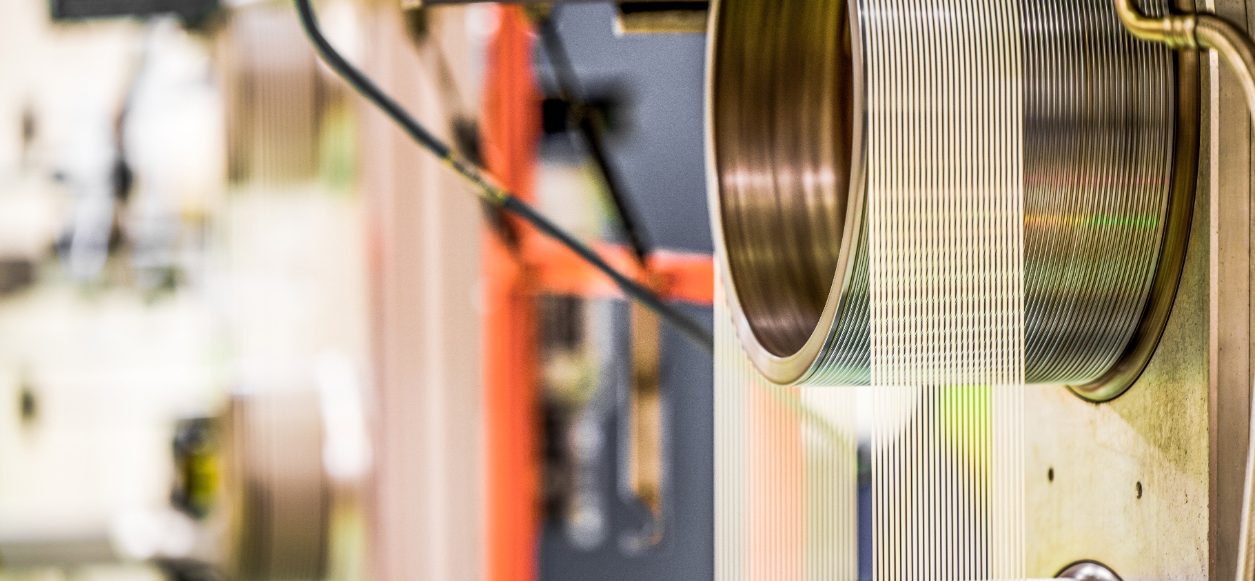

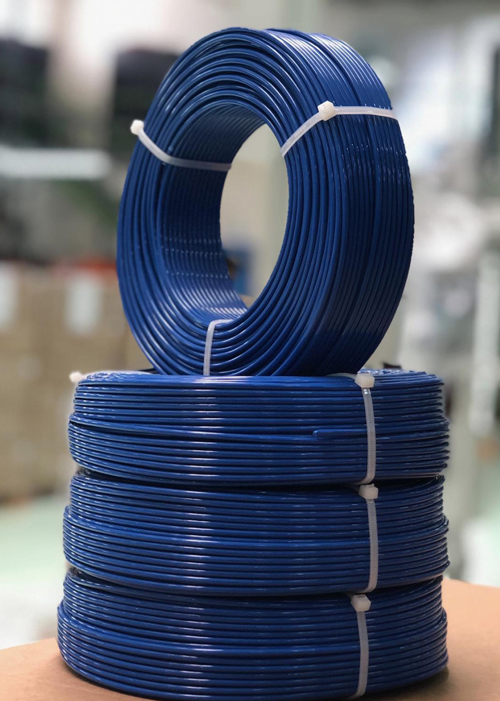

These test pieces are printed using a Volumic MK2 printer, utilizing materials infused with carbon fibers, fiberglass, algae-derived components, as well as materials originating from plastic injection.

3D printing enables the rapid creation of test pieces with various materials and different printing profiles (temperature, infill ratio, print speed, etc.)..

Volumic 3D

- May/2023 -

09/05/2025 © All rights Reserved. GEMEA Interactive