Mr. Riffaut, Methods / Maintenance / Continuous Improvement Manager at Bernadet, shares his experience with 3D printing:

"In 2018, Bernadet brought the production of its tools in-house through additive manufacturing. In addition to being based in France, Volumic offers high-performance and reliable equipment, along with responsive and quality customer service. This partnership has brought us numerous benefits:

- Significant cost reduction

- Extremely short lead times

- Easy prototyping and development

- Cost-effective adjustments/modifications

- Strengthening of internal skills

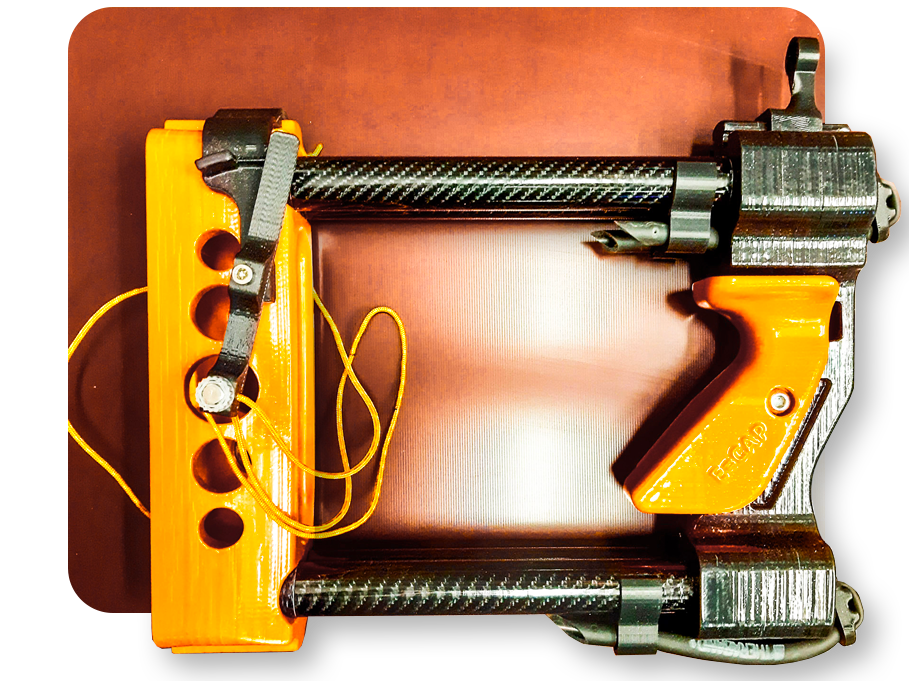

The showcased station consists of 11 3D-printed components and is part of a semi-automated production line with a total of 147 components, all developed in-house."

Volumic 3D

- May/2023 -

25/12/2025 © All rights Reserved. GEMEA Interactive