Virbac Group, a 6ᵉ global veterinary pharmaceutical group, relied on Volumic 3D printers to develop a completely innovative animal health sampling cap.

The advantage of liquid medication is that the amounts of the product to be administered can be precisely measured based on the weight of the animal (or the person) being treated, thus preventing over- or under-dosage.

On the other hand, the main challenge of liquid medications lies in the potential risk of contamination for the product user. Particularly in the veterinary field, avoiding any contact with individuals living around the treated animal is always imperative due to the possibility of the medications being inappropriately concentrated for humans or raising specific toxicological concerns.

This poses a challenge for pharmaceutical companies: to find the right packaging system that is perfectly suited to achieving this goal, while also remaining user-friendly, in order to provide security, instill confidence, and ensure treatment adherence.

This is what Virbac’s Smart Capoffers, a comprehensive, secure, and straightforward solution that adheres to best medical practices, thereby enabling better application of liquid products by users. This cap represents a groundbreaking innovation in animal health as well as human health.

In practice, this cap enables a clean and contactless product extraction process. The system is needle-free, eliminating the need to puncture the elastomeric cap.

The user securely extracts liquid from a bottle by directly connecting a syringe to the cap.

An integrated air vent facilitates the extraction process and maintains the cleanliness of the product during its use.

The opening and closing system is intuitive, meeting both the criteria of "child-resistant" and "senior-friendly" design.

Over the course of the 5-year development period, some of the 10 components of this cap were able to evolve through 3D printing, thanks to the responsiveness of Volumic Company. In a traditional process, such component enhancements in injection-molded parts would have required new prototype molds, entailing delays and costs.

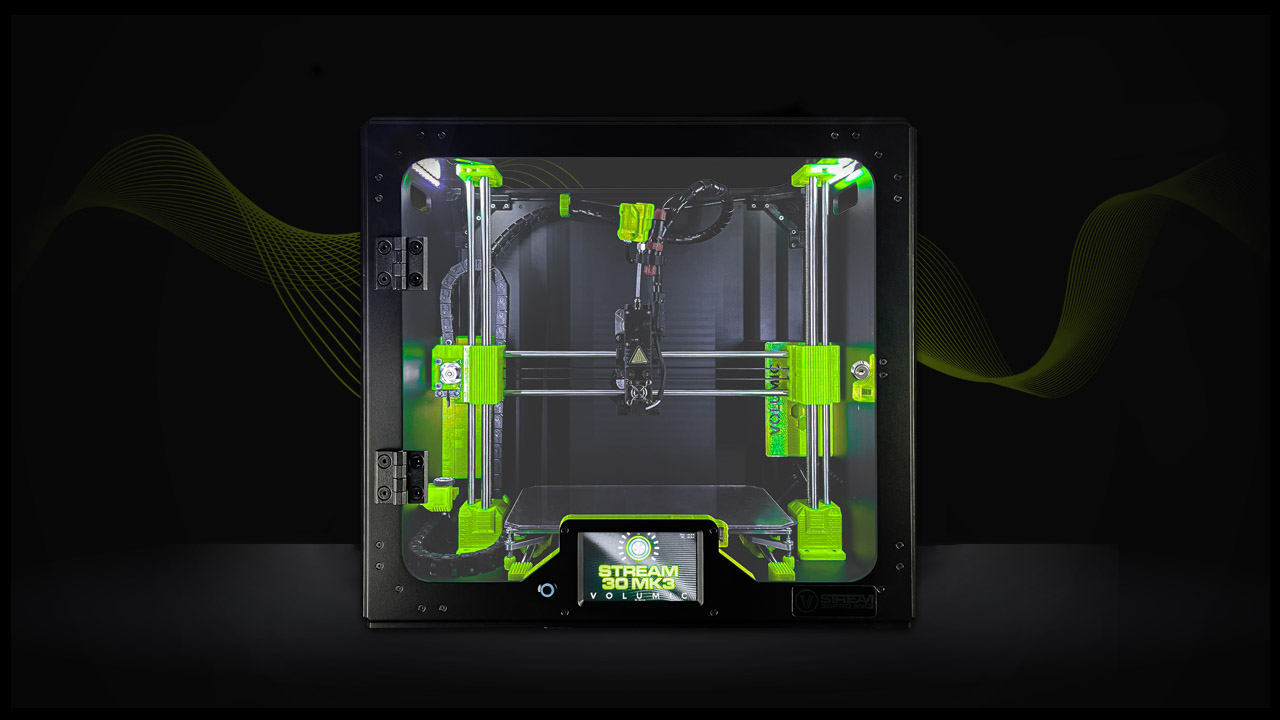

Thanks to the Volumic Stream 30 Pro MK2 3D printer, they were able to produce prototypes using materials that closely mimic the mechanical properties of the original parts. This allowed them to test and validate these components in-house within a few days, at a cost of just a few euros. Most importantly, this rapid turnaround enabled a successful product launch on schedule, thereby avoiding the potential impact of several months' delay.

Additive manufacturing has revolutionized our daily work, and the purchase of the Stream 30 Pro printer was able to be paid off within just one month!

Volumic 3D

- May/2023 -

24/12/2025 © All rights Reserved. GEMEA Interactive