Nice Côte d'Azur Airport 3D prints components that are used in their daily operations, such as luggage diverters and radio supports for firefighting intervention vehicles.

These components are printed in PLA and PETg for their strength, using two Stream MK2 printers, each with around 4000 hours of printing time.

3D printing not only saves time and money by eliminating the need to order these wooden parts, but also allows for adjustments to the angle or length of the piece to make it more efficient.

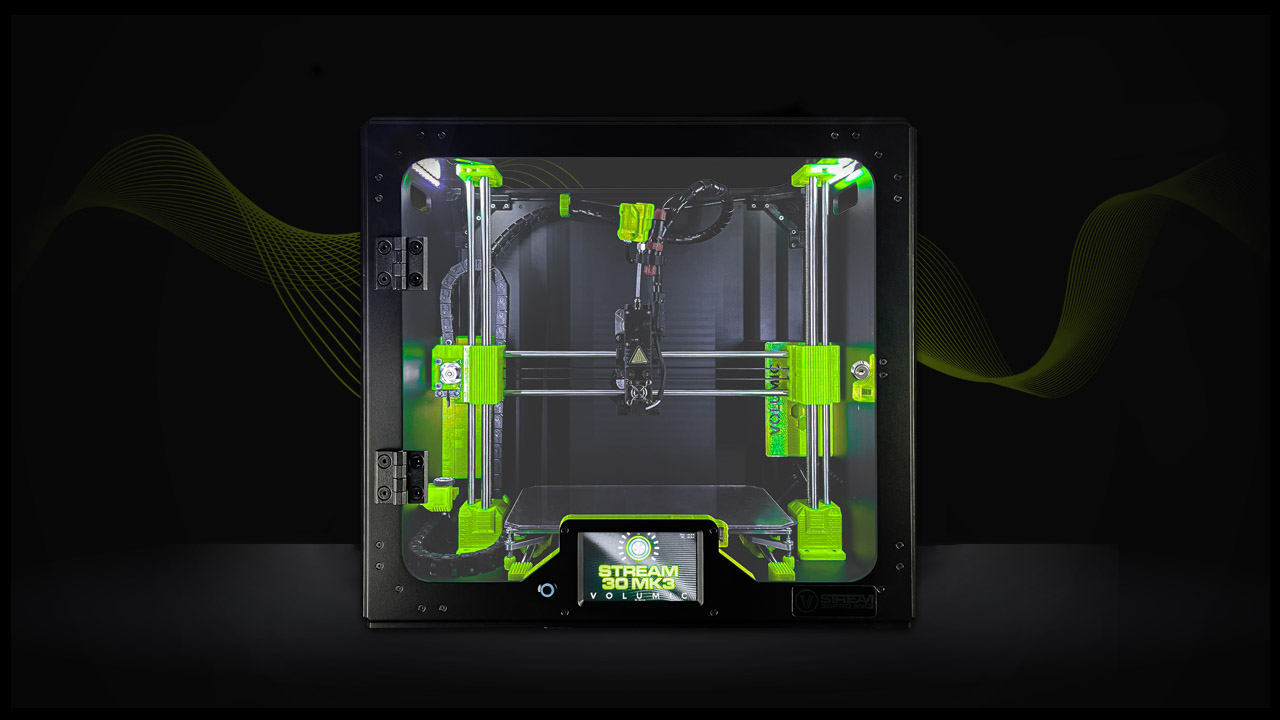

MK3

Volumic 3D

- May/2023 -

13/07/2025 © All rights Reserved. GEMEA Interactive