Cerballiance Côte d’Azur laboratories have developed an interface for integrating automation within the laboratories.

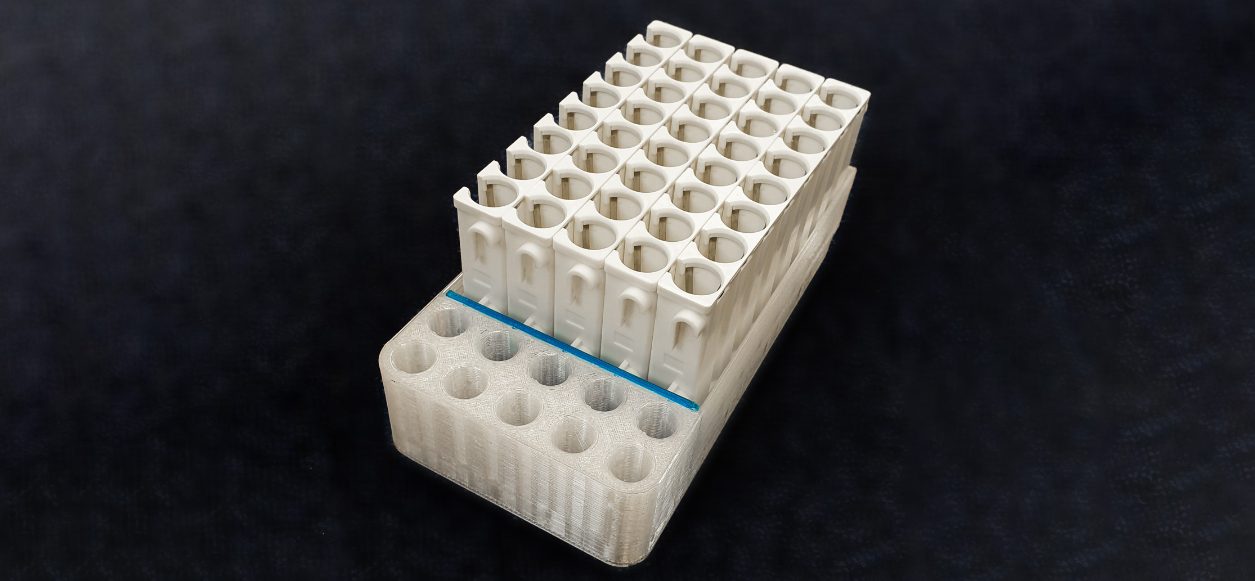

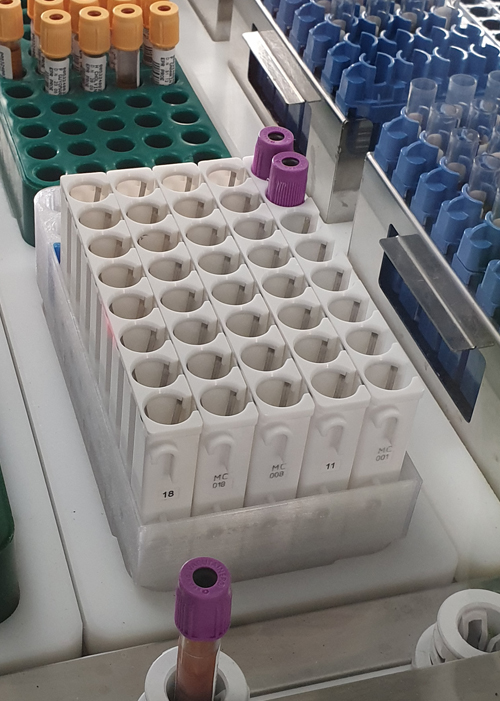

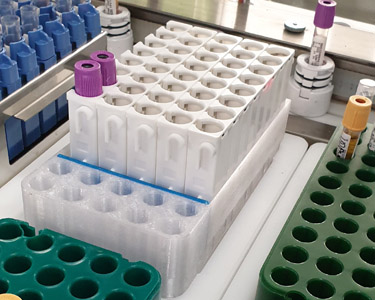

Every day, 150 tubes had to be manually sorted due to the lack of standardization among various tube and automation brands. This tedious and ungratifying task is now automated through these rack holders, which make the different components placed in the sorting area compatible.

The automatons sort the samples based on cap color and label, arranging them neatly on the racks held by the holders printed on Volumic 3D printers.

During the first lockdown, Dr. Vincent RAIMONDI and Cerballiance laboratories had already teamed up with 3D printing for the production of test cups used in COVID-19 PCR screening.

Volumic 3D

- Apr/2023 -

18/07/2025 © All rights Reserved. GEMEA Interactive