For approximately 3 years, the French manufacturer of 3D printers Volumic has been working closely with the PSA Group for the production of parts, including functional prototypes, tooling, and finished components.

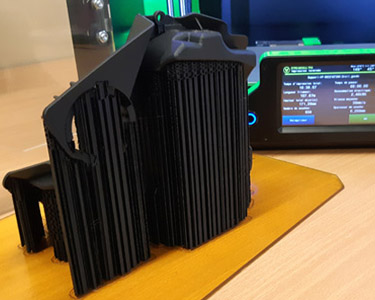

The automotive manufacturer has indeed invested in desktop FDM machines from the Stream ULTRA and MK2 series, primarily for its Service and Parts department, which corresponds to the group's after-sales service. This allows them to manufacture components using technical materials and loaded filaments from the Volumic range, meeting industry standards and constraints in terms of heat resistance, mechanical stress, and wear.

Additive manufacturing has a prominent position in the automotive sector where it assists manufacturers in creating more complex and customized parts within shorter timeframes. Developments in materials also enable the design of projects that meet the requirements of this industry, regardless of the chosen printing technology. In fact, the PSA Group had showcased its innovations in this field three years ago its DS 3 Dark Side which included, for example, 3D-printed titanium parts. If metal additive manufacturing is an increasingly employed process among manufacturers, fused deposition modeling is not lagging behind, and the collaboration between PSA and Volumic is a testament to that.

For the PSA Group, relying on a French 3D printing industrial partner was crucial. After testing various technologies such as SLS, MJF (Multi Jet Fusion), the company turned to FDM. At this point, several brands were available to them. Mr. Alexandre, Director of Service and Parts, explains: " We chose Volumic because their machines are Made In France and offer performance that meets our expectations. Additionally, their customer support is easily accessible, which was part of our decision criteria. We indeed need to be responsive and have the simplest possible communication. " The manufacturer first invested in a Stream 30 MK1, which quickly evolved into MK2 following the new features introduced by the Nice-based brand. Impressed by the scalability and reliability of the machines, the Service and Parts department then chose the new ULTRA range from Volumic In order to expand its portfolio of applications with an ever-increasing number of compatible thermoplastics.

A French collaboration that meets multiple expectations.

Today, Mrs. K. SAUNAL confirms that Volumic's machines allow her to accelerate the prototyping phase by aiding in quicker and more efficient management of geometry and assembly challenges in complex assemblies. It's worth mentioning that with its ULTRA range, Volumic aims to offer high-speed performance, which has saved the automotive manufacturer a considerable amount of time. The machines are also compatible with a wide range of filaments, from standard materials to technical thermoplastics, enabling the production of parts with mechanical characteristics varying based on the final application.

Mr. R. SULTER explains that certain parts are printed to validate concepts or functional volumes, reducing production times and costs. For instance, the engine assembly line for EB generation gasoline engines employs a dedicated MK2 3D printer to produce camera mounts, inspection jigs, gaskets, brackets, and more. The manufacturer specifies: " Parts that used to cost us 300 or 600€ or more, with tight delivery schedules, now cost us around 2€ and are available within a few hours! This has reached a point where our workshop's machine was paid off in less than 2 months (including consumables). »

Supporting and providing training

If the introduction of 3D printing has enabled the group to increase efficiency, it's largely because it has managed to organize dedicated workflow processes and training on machine operation, supported by Volumic. It's necessary to prioritize projects, establish usage rules, and train operators, among other things. Currently, access to the machines is only granted to individuals associated with a department that has a 3D printer and possesses the necessary 3D printing skills. Print scheduling is managed internally by a designated user within each department. Mr. Alexandre adds: " Having completed a training program as a 3D Printing Project Manager, I brought my skills to the initial users during the implementation of the first Volumic machines within the Group. The Volumic teams are also always available to listen to us and address our challenges."

Stéphane Malaussena, co-founder of Volumic, concludes: " In addition to the quality of our products, our clients also appreciate the support, advice, and guidance we provide them with through our expertise in this technology. The best recognition of the quality of the work we do is reflected in the trust placed in us by numerous major players in cutting-edge sectors such as Automotive, Aerospace, Energy, R&D, Veterinary, Pharmaceutical, and more. We are happy and proud of the nature of our relationship with PSA, which, in a broader sense, is excellent news for the advanced French industries (both automotive and 3D printing)." You can find more information about this on the Volumic 3Dprinters on the company’swebsite..

In terms of modeling, the "After-sales" department is now self-sufficient and can manage a project from the study phase to final production. It is equipped with two 3D scanners and has expertise in methods such as reverse engineering and topological optimization.

Volumic 3D

- May/2023 -

26/01/2026 © All rights Reserved. GEMEA Interactive