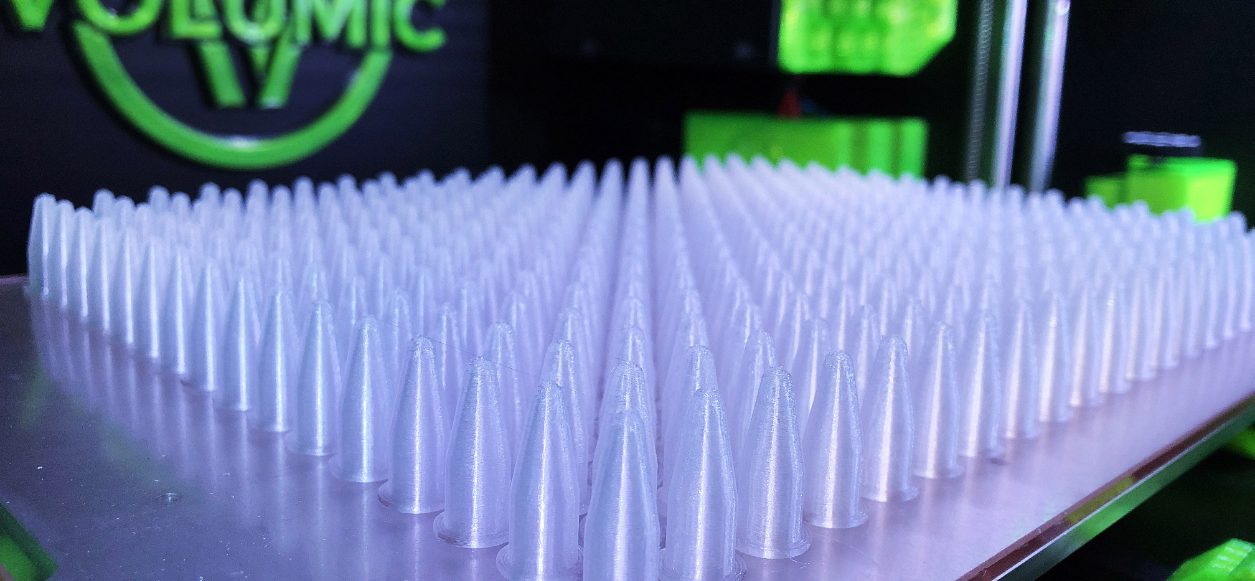

Within 72 hours, a thousand COVID-19 analysis test swabs 3D-printed.

The Laboratories CERBALLIANCE, VOLUMIC and LaFERME3D have joined forces to provide an unprecedented solution to the issue of testing kit shortages for COVID-19 thanks to 3D printing.

CERBALLIANCE, which comprises 600 diagnostic laboratories in France, has been designated by the ARS (Regional Health Agency) to conduct COVID-19 screening tests. In this capacity, it is equipped with several state-of-the-art screening automatons capable of performing over 150 analyses per day each.

However, due to the unprecedented magnitude of the threat, the laboratories do not possess a sufficient quantity of test cups to operate their automatons at full capacity. With suppliers unable to fulfill their customers' requests, the official supply chain has been disrupted. The global shortages of test cups are effectively rendering these crucial machines inactive in the relentless battle against the virus!

In an urgent response, Dr. Vincent RAIMONDI, General and Medical Director of CERBALLIANCE Côte d’Azur, reached out to VOLUMIC with a singular goal: to swiftly design and produce an alternative, validated version of these test cups!

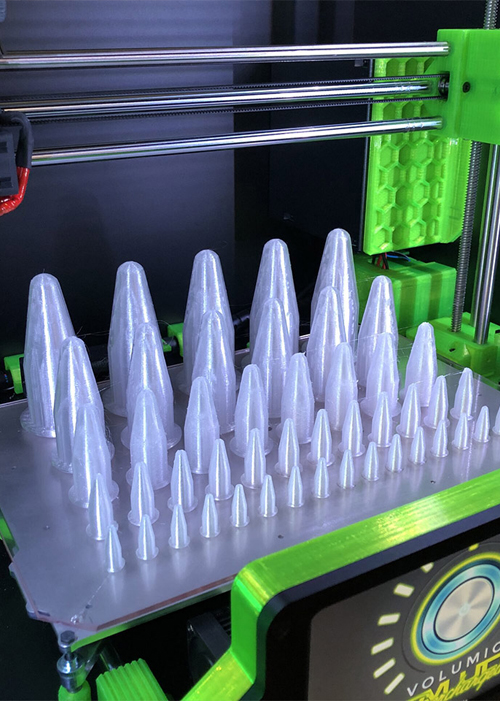

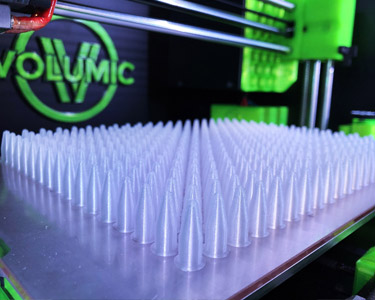

In under 72 hours, leveraging the expertise of FERME3D (particularly in areas of sealing and mass production), VOLUMIC successfully provided a 3D-modeled and printed version of the test cups to Dr. RAIMONDI's team. Subsequently, technical validation analyses were initiated, confirming that this new equipment could substitute the missing versions alongside the testing kits.

Consequently, VOLUMIC and FERME3D are gearing up to manufacture this essential consumable for conducting SARS-CoV-2 RT-PCR screening tests on a large scale. These screenings will be primarily offered to healthcare personnel to more accurately assess and monitor the infection status of medical professionals on the frontlines of the COVID-19 battle.

Rapid COVID-19 screening stands as a crucial link in comprehending its spread and, subsequently, validating the epidemic's control, thereby enabling a secure transition back to a "normal" life.

In less than 72 hours, 3D printing has delivered a vital and tangible solution (from prototype to mass production) to a sector known for its precision, at a time when its supply chain was under critical strain. This innovative solution reinstates the full potential of the screening automatons, enabling them to operate at maximum capacity and thus urgently addressing the exponential demand for testing across the nation.

On a broader scale, the validation of the 3D-printed test cups' reliability by the medical laboratory CERBALLIANCE and its reagent suppliers will trigger a strategic contemplation post-crisis regarding the constraints of conventional manufacturing methods and their critical dependencies on foreign suppliers.

Simultaneously, and in close collaboration with health and scientific authorities as well as the international 3D printing community, VOLUMIC and La FERME3D have embarked on other avenues to combat the virus's spread through 3D printing technology.

More than ever, 3D printing showcases its agility and vast potential for response, even in unprecedented crisis situations!

Volumic 3D

- May/2023 -

05/07/2025 © All rights Reserved. GEMEA Interactive